We have all asked these questions before:

- Should I just sketch each of these 4, 6, 8, etc. items or sketch it once and pattern it?

- How easy will it be to change if I pattern these items?

- Will my model history and process make sense?

- What will I really be saving on file size if I use patterns?

- Will my model be more efficient to edit?

- How healthy is a model with patterns versus a model without patterns?

- For that matter…. do I pattern the sketch items or pattern the features or just sketch each item separately and generate features from those individual sketches?

Mankind has never faced such daunting questions before….. okay, well maybe a time or two.

The simple truth about 3D parametric modeling is you have a short checklist that you should adhere to for every part model you create. Unfortunately not everyone follows these simple rules (you know who you are)….and by doing so, it creates some major headaches for the rest of us. Just think of those exploded dimensions back in an old AutoCAD DWG….. exploding dimensions, what purpose did that serve and how much work did it take to work with and around those exploded dimensions? 3D Parametric modeling is no different. We all need to be on the same page for modeling as best as possible. Here are some things to keep in mind when modeling:

- Create an accurate model – The 3D model might as well be a bitmap image if it does not accurately represent the design intent. Patterns have accurate controls.

- Create a stable model – stability is key when changes are necessary and if a simple change causes the model to explode with errors, then excessive work is required in order to repair the damage. Patterns can help here.

- Create a model that is easily understood and changed – this couples with the previous item. A model that is complex and cannot be followed easily may frustrate the next user and they may waste time recreating another copy from scratch simply because they couldn’t understand your modeling workflow/logic. We do not all think the same but basic, unified (agreed upon) approaches to modeling similar geometry bodies can be used to make changes and diagnose geometry workflow easier. Patterns are easily deciphered.

- Your model should be efficiently designed. Okay, so this one can be a stretch but if you can generate an accurate, stable, easily changed model. Why not do so in as few steps as possible? This is where planning and hand sketching can have a tremendous payoff. This can reduce file size, reduce design time (once you get a system in place to model efficiently). This is typically handled via templates, which is the simplest and most efficient way, but there are other ways too such as sketch blocks, templates per shape/size, material styles that only contain company used materials, etc. We’ll make this step an optional one. Patterns often enter this phase because you have to determine if anything can be patterned and if so, what can be and where do you pattern it (as a sketch or feature….or even a part pattern in an assembly).

|

|

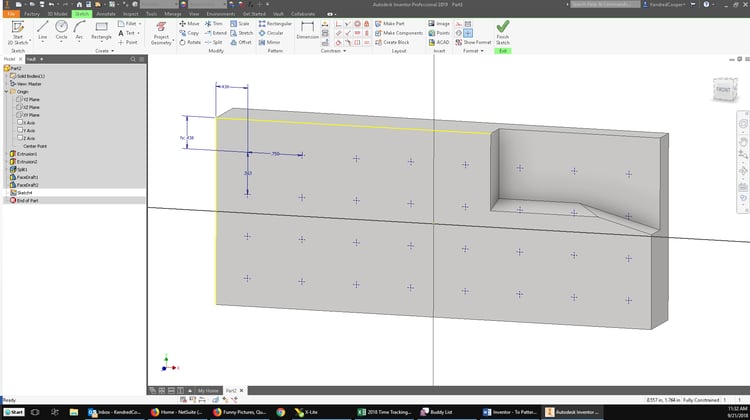

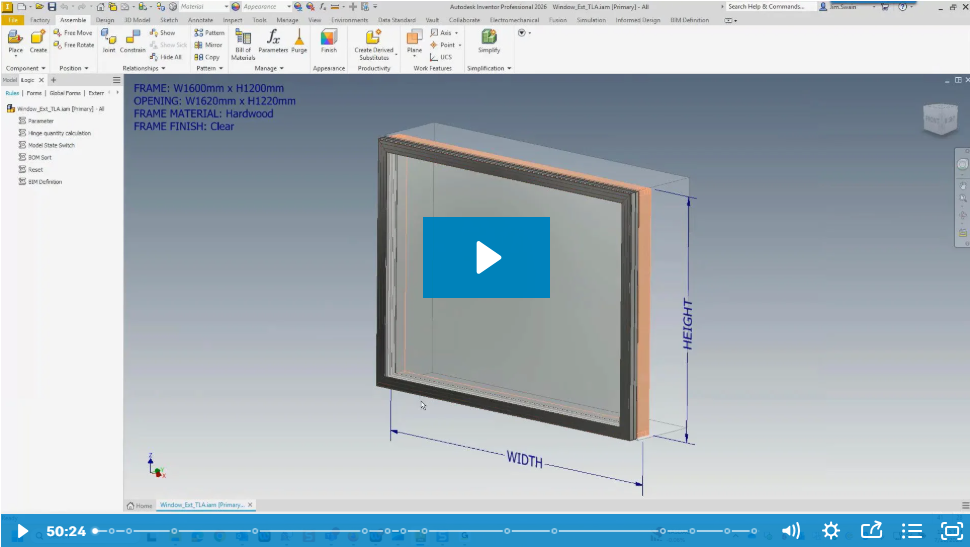

Figure 1 |

When considering whether to pattern or not, the first question that should be asked is… at what quantity do I pattern versus create each item separately? Do I place 4 holes that are the same or do I place one and pattern it? Obviously this is *not* an easy one to answer because it depends on what geometry you’re modeling. If you are drilling 20 equally spaced, same size/type holes, then for me, it’s faster if I sketch a single point, sketch pattern that point and then use the Hole command to drill holes based on the location from the sketch pattern points. However, if you’re drilling 20 different holes consisting of 3 different types, 6 different sizes and they are *not* equally spaced….then this one is a challenge to model efficiently and/or pattern.

|

|

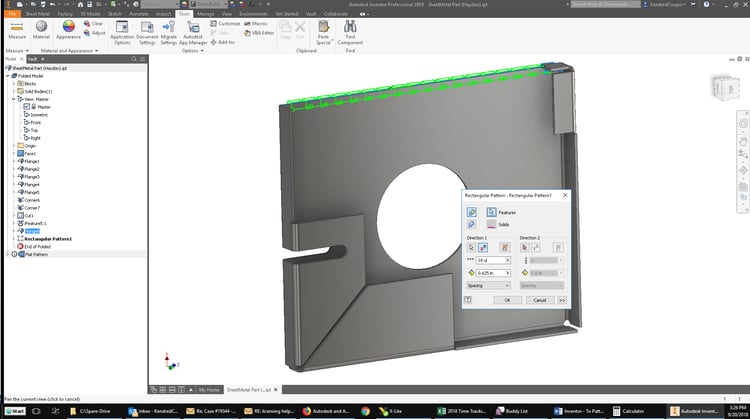

Figure 2 |

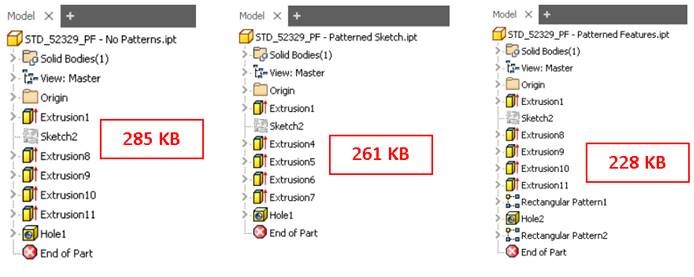

One concern that still lingers is the issue of file size. We’re all still acting like everything has to fit on a 1.44MB 3 ½” floppy disk (Google® it if you’re not sure what that is). While keeping file sizes down continues to be a goal and can benefit performance (main system and programs too), it doesn’t even crack the top 10 list on modeling goals, but we’re going to look at it anyways as part of this article. Taking the same model geometry and creating the design without patterns vs sketch patterns vs feature patterns, you’ll see that the file size impact is negligible. Notice the modeling tree in Figure 2 compared to the impact each modeling process had on the file size shown on each image.

|

|

Figure 3 |

While modeling a set of features and then patterning the needed features yielded the lowest file size, for efficiency and simplicity of making changes, depending upon the geometry and possible anticipated future changes, patterning features may not be the best workflow.

To pattern or not to pattern: If you can complete the model faster while adhering to most of the above items then your model will be grade A, top of the line and will provide hassle free interaction. We’ve all got enough headaches getting all of those TPS reports done. We don’t need modeling headaches too. That reminds me…..where is my red stapler?!?!

Comments