Your day-to-day as an engineer likely involves as much constant learning as it does constant work. Technology is racing forward – bringing advancements that promise to streamline your workflows.

But navigating and understanding the potential of technology can be as time-consuming as it is helpful.

At Hagerman, we bring decades of experience helping engineers and other professionals navigate new ways of using their technology. Here, we provide an extensive guide to modern engineering document management. This resource delves into the cutting-edge tools and strategies essential for mastering document control in an era where efficiency is king.

We'll address each of the following topics:

- What Are the Top Questions Engineers Have About Document Management Support?

- What Are the Best Practices for Document Management Implementation?

- Which Document Management Systems Are Best Suited for Engineers?

- How Does Engineering Drawing Document Management Compare: Vault vs. Windows Folders?

- Why Does My Organization Need an Electronic Document Management System?

- What Are the Essential Tips to Prepare for Legacy Data Migration?

- How Can a Document Management System Improve Operations in Manufacturing Plants?

- What Are the Pros and Cons of Enterprise Document Management Solutions?

- How Can I Improve My Facility’s Document Management System?

- What Are the Benefits of Using CAD Document Management Software?

- How Is Autodesk Document Management Shaping Modern Engineering Workflows?

- How Do Engineers Utilize Connected Product Development to Break Down Silos?

- In What Ways Is Document Lifecycle Information Management the Future of Plant Process Engineering?

- How Does Unifying Manufacturing Operations With Integrated Factory Modeling Empower Businesses?

- What Strategies Can Overcome the Manufacturing Talent Shortage Through Automation and Efficiency?

- What Are the Future Trends in Engineering Collaboration and How Can We Sidestep Roadblocks?

- What Should I Expect From Document Management Consulting Services?

1. What Are the Top Questions Engineers Have About Document Management Support?

The complexities of document management can be challenging for engineers. As the world moves more towards automation and the future role of AI, it’s vital that engineers understand how to take advantage of technology for their documents.

Engineers frequently ask our team about the support available for document management. The top questions include the following:

-

What can Autodesk Vault® really do for me?

-

How do I assess my current document management environment?

-

Are there any online trainings I can reference?

-

How can document management support & training help my engineers around the world?

-

How does Autodesk Vault® prepare engineers for the future?

Learn their answers in this article!

2. What Are the Best Practices for Document Management Implementation?

The right document management system can transform how engineers store, access, and manage documents and data. Implementation success hinges on a strategy that is both easy to follow and secure. Here are the must-follow best practices.

-

Perform an assessment of current document systems

-

Prioritize security and access control

-

Ensure integration with existing systems

-

Regular training and skill upgradation

-

Maintain regular backups and establish a document lifecycle

"If a company is using a 12-year-old system, even if it's outdated, as long as it's digital and has some organization, we can modernize it with our current technology."

- Andrew Hagerman, Director of Sales at Hagerman & Company

3. Which Document Management Systems Are Best Suited for Engineers?

There are numerous document management systems available in modern engineering. The amount of choices can overwhelm even the most seasoned engineers. Here’s the lowdown on the top contenders.

-

Autodesk Vault® is a good platform for product engineers as it offers version control and many integration options.

-

Autodesk Docs® works best for AEC and construction engineers with its cloud-based platform.

-

Fusion Manage® offers a cloud-based system for cross-disciplinary teams. It blends product lifecycle management with unmatched flexibility.

-

Vault PLM excels in managing complex product data and processes, ideal for large enterprises needing deep control and integration. It merges Vault Professional with Fusion 360® Manage.

-

Meridian caters to manufacturing plant engineers. It excels in compliance and centralized control.

-

Windows File Explorer and Google Drive offer basic solutions for those seeking simplicity.

-

Dropbox, Microsoft SharePoint, and OneDrive provide various levels of integration and user-friendliness but may fall short in delivering the specialized tools and features engineers need.

4. How Does Engineering Drawing Document Management Compare: Vault vs. Windows Folders?

Are you still managing your CAD files with Windows Folders? For years, it’s been a familiar system for engineering drawing document management. But the simplicity of the platform often masks underlying limitations. It might be familiar to you, but there’s a better way.

One option is Autodesk Vault®, a specialized PDM tool that caters to the nuanced needs of engineers. It’s built to streamline collaboration by being a vital part of projects.

5. Why Does My Organization Need an Electronic Document Management System?

Your organization most likely has other systems that can store documents – PMIS, CMMS, or similar platforms – so why invest in an electronic document management system (EDMS)? Unlike those specialized systems, EDMS serves as a central repository for all documents, regardless of their business function.

“A properly configured EDMS can work WITH all (most) other systems to become the source of truth regarding documents. It will stand the test of time long after the other systems have gone.”

- Jennifer Sample, Hagerman & Company

6. What Are the Essential Tips to Prepare for Legacy Data Migration?

Did you know that, according to the Harvard Business Review, data-driven organizations are 23 times more likely to outperform competitors in customer acquisition, nine times more likely to retain customers, and up to 19 times more profitable?

But as the world has changed drastically, many organizations deal with a significant amount of valuable legacy data. It’s tricky to access that data while it can remain the backbone of an industrial operation.

Legacy data migration is a delicate process that Hagerman specializes in. To prepare, we take the following steps.

-

Evaluate current legacy data systems

-

Audit existing data and system dependencies

-

Ensure data integrity during migration

7. How Can a Document Management System Improve Operations in Manufacturing Plants?

Efficiency, efficiency, efficiency. That’s the word in manufacturing plants. Each process is an opportunity to improve operations and save costs and time.

via Hagerman

via Hagerman

“I suspect [the modern era] will realize increased tech utilization to improve the process itself with some evolutionary advancements in the tech.”

- Tim Shinbara, Vice President and CTO for the Association for Manufacturing Technology

The right EDM software, such as Vault or Meridian, can be optimized to create a better solution for storing and organizing documentation. When this is done right, it creates a central repository of documents, making it more simple to oversee and manage the manufacturing process.

To ensure you’re utilizing your engineering document systems at the most optimal level, follow the 10 steps in this article.

Want to learn more about how manufacturing leaders are changing factory design through innovative tech? Read our free guide:

8. What Are the Pros and Cons of Enterprise Document Management Solutions?

Adopting an enterprise document management solution is a smart move that will significantly improve your organization’s collaboration and efficiency. However, there are pros and cons, and it’s important to weigh both sides of the coin.

Pros:

-

Enhanced Collaboration and Accessibility: EDMS streamlines document handling processes.

-

Increased Security and Compliance: Keep up with regulatory requirements with easy access to document history and revisions.

-

Streamlined Workflows and Productivity: Automate routine tasks like data entry, document routing, and management.

Cons:

-

Initial Setup and Training: Learning a DMS can be a significant undertaking without a teacher.

-

Integration Challenges: While these DMS systems are designed to integrate with CAD systems, errors can happen without an expert on hand.

-

Data Migration and System Maintenance: File format conversion and new system organization come with inherent risks without an expert.

9. How Can I Improve My Document Management System in Campus Facilities?

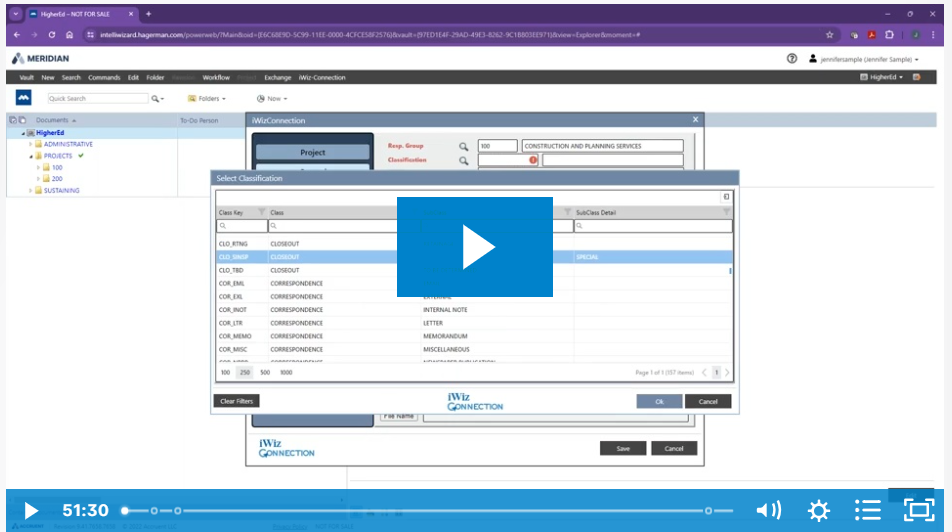

Research shows that leaders spend nearly 40% of their time making decisions. In facility management in higher education, implementing a well-structured document management system, like Meridian, can be a game-changer in saving time.

But what are concrete action steps to get started? Begin with these three strategies.

-

Centralize document access and metadata linking

-

Customize Meridian for specific institutional needs

-

Integrate existing facilities systems with Meridian

10. What Are the Benefits of Using CAD Document Management Software?

It’s not uncommon for engineers to get lost in the chaos of day-to-day work life, riding the waves of business rather than innovating. However as automation continues to drive business growth, it provides an opportunity for self-assessment. For example, you might use CAD document management software. Explore the benefits of the software in this article.

If you don’t feel like you’re taking advantage of these benefits, take a moment to break down your process and see where the gaps are. If you need help, Hagerman helps companies like yours do this every day.

11. How Is Autodesk Document Management Shaping Modern Engineering Workflows?

Autodesk document management is revolutionizing modern engineering. It provides advanced tools that allow engineers and project managers to streamline data access, enhance collaboration, and boost project efficiency.

Further, the system fosters an environment where real-time updates and feedback are common. The immediacy of this reality speeds up decision-making processes and breaks down silos.

These innovations might seem small, but the influence is felt beyond document management and handling. By reducing countless minuscule tasks, engineers can supercharge their team.

Learn leaders’ insights on how digital transformation is driving business resilience, sustainability, and talent management in this infographic.

12. How Do Engineers Utilize Connected Product Development to Break Down Silos?

The Harvard Business Review says that almost 80% of employees believe that automation has given them more time to “take on challenging new projects and learn new skills.”

For product engineers, utilizing connected product development is a way to tap into the benefits of automation. Tools like Autodesk Vault or Inventor® help engineers eliminate manual data entry and minimize errors when transferring information from design to production.

“For many engineers, they just need to start somewhere to connect their systems. If there's ‘if-then’ logic in their product workflows, then we can automate it. If you’re walking off the beaten path, you’re going to need a hatchet to get back on the path. But it’s worth it.”

– Ken Christensen, Sales Manager at Hagerman

13. In What Ways Is Document Lifecycle Information Management the Future of Plant Process Engineering?

Overseeing a large-scale project means orchestrating a balancing act. You must manage documentation, different teams, strict compliance standards, and client demands. Wouldn’t it be great if that all could be managed in one place?

Automating document lifecycle information management is possible with tools like Autodesk. It streamlines your projects at every phase – from initial planning to maintenance schedules. What this means is better engineering document management means better efficiency and accuracy. The world continues to move in this direction, and it will only grow in significance within the future of plant engineering.

14. How Does Unifying Manufacturing Operations With Integrated Factory Modeling Empower Businesses?

It’s an unfortunate reality that most factory planning projects do not meet time and cost goals: 72% are over budget and 60% are over time.

You can avoid these trends through the concept of Integrated Factory Modeling. This is a strategy that unifies Building Information Modeling (BIM) and digital factory systems – creating one single source.

This approach harmonizes disparate processes and creates a cohesive, digital representation of the factory floor. It’s a way to model out information and view it in real-time. This will streamline manufacturing operations, mitigate risks, and boost accuracy.

“Manufacturers need to be nimble enough to quickly make changes on the manufacturing line when there are issues with a product. With Integrated Factory Modeling, teams can easily see what is happening on the manufacturing floor and unify their operations for a better, more agile manufacturing facility.”

- Jeremy Stefanek, Director of Sales – Customer Success and CAD Solutions at Hagerman & Company

15. What Strategies Can Overcome the Manufacturing Talent Shortage Through Automation and Efficiency?

Over the last decade, 2.4 million industrial jobs in the United States went unfilled – and that cost the economy $2.5 trillion. How can you combat this trend and address the talent shortage? It starts with understanding and utilizing modern technology.

There are five key areas of opportunity:

-

Automation Solutions

-

Collaborative and Knowledge-Sharing Platforms

-

Increase Process Efficiencies

-

Training and Skill Development

-

Workforce Planning and Optimization

Learn how to overcome the manufacturing talent shortage in this article.

16. How Can We Sidestep Roadblocks in Engineering Collaboration?

Roadblocks and bottlenecks are a disaster for any type of project. In engineering, where projects are complex and long-scale, the stakes are even higher. You must balance meticulous planning and a strict adherence to budgets, timelines, and safety standards.

Tools like Autodesk can help bridge these gaps and transform data silos into streamlined workflows. Your organization has the opportunity to flip these challenges into opportunities. To gain important insights, manage more work with the same amount of people and improve overall decision-making.

For example, look at what a Common Data Environment does for EPC contracting:

17. What Should I Expect From Document Management Consulting Services?

Technology can revolutionize your operations – but only if you get the right support.

When hiring a document management consulting service, expect a tailored strategy that aligns with your goals. Experts like Hagerman’s team dive deep into your current system and pinpoint inefficiencies. Then, they craft a roadmap for action that takes your projects into account.

At Hagerman, we bring seasoned professionals who know how to target problems for our clients. We connect, improve, and automate the EDM systems within your company.

Learn more about how our process can help you today!

Comments