In today’s fast-moving engineering and design environment, efficiency isn’t just important—it’s a competitive advantage. Yet many organizations struggle with CAD environments, weighed down by slow workflows, repetitive manual tasks, and inconsistent standards. These challenges don’t just frustrate teams; they create costly delays and rework.

That’s where CAD consulting makes an impact. By partnering with specialists who focus on workflow optimization, automation, software configuration, and training, companies can uncover inefficiencies and turn their CAD systems into engines of productivity. Instead of guessing where improvements are needed, consulting provides structured assessments and measurable outcomes.

In this guide, we’ll explore the most important questions organizations ask when evaluating CAD consulting services, including:

-

What is CAD consulting, and how can it help my organization?

-

How do I choose the right CAD consulting service for my needs?

-

What are the key benefits of using a CAD consultant over internal staff?

-

How do CAD consultants help optimize or automate CAD workflows?

-

What is included in a typical CAD consulting engagement (scope & deliverables)?

-

What are common challenges in CAD software implementation—and how do consultants solve them?

-

How can a consultant support migrating legacy CAD data and systems?

-

How do consultants approach training or upskilling in-house staff?

-

What do CAD consulting projects cost, and what kind of ROI can I expect?

-

Can solutions and support be provided remotely or virtually?

-

What should I expect as ongoing support after a consulting or implementation project?

-

How does a CAD consultant ensure data security and intellectual property protection?

-

Can a consultant customize CAD solutions for our industry (AEC, manufacturing, etc.)?

-

How do consultants help solve specific modeling or geometry problems?

-

What’s the difference between a CAD health check and a full implementation project?

-

What are the latest trends and best practices for CAD adoption in engineering and manufacturing?

As you move through each section, you’ll find actionable takeaways to help you decide if CAD consulting is the right step for your organization.

What is CAD Consulting, and How Can It Help My Organization?

A study conducted by Tech-Clarity revealed that engineers can spend up to a third of their working hours on non–value-added tasks, and 20% on managing outdated data. That’s time lost to inefficiencies—undermining deadlines, budgets, and long-term growth.

CAD consulting solutions solve this by taking a holistic look at your design ecosystem: software, workflows, data, and team skills. Consultants uncover bottlenecks, streamline processes, enforce standards, and automate repetitive tasks. This turns CAD from a drag into a performance driver. The results? Faster delivery and fewer mistakes, leading to more time for innovation.

Key benefits of CAD consulting include:

- Workflow optimization for faster project delivery

- Standardization to improve design quality and consistency

- Reduced rework through stronger processes and automation

- Team efficiency gains with better training and tools

For a deeper look at how CAD consulting improves data management and team productivity, you can dive into Why You Need CAD Consulting for Better Data Management.

How Do I Choose the Right CAD Consulting Service for My Needs?

Not all CAD consulting services are created equal, and choosing the wrong partner can leave you with the same inefficiencies you started with. The best consulting engagement begins with a provider who understands your industry and your long-term goals.

When evaluating CAD consulting services, organizations should:

-

Define specific pain points and objectives

-

Evaluate consultant expertise in their industry

-

Review service offerings and methodologies

-

Consider scalability and long-term support

-

Verify the organization’s certifications and partnerships

-

Request case studies and references

These steps provide a practical framework for selecting the right partner. For a deeper breakdown of each, see our article on Steps to Choose the Right CAD Consulting Service.

What Are the Key Benefits of Using a CAD Consultant Over Internal Staff?

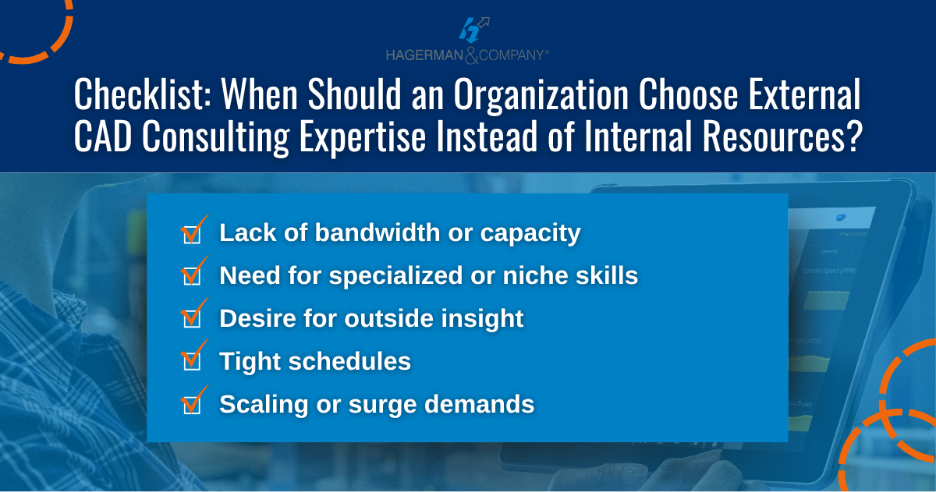

When internal teams manage every aspect of CAD systems, they often face limited bandwidth, competing priorities, and blind spots in their workflows. Partnering with a CAD consultant helps bridge those gaps by offering specialized expertise and proven best practices without adding long-term overhead.

CAD consultants bring broad, cross-industry experience that allows them to quickly identify inefficiencies, apply proven solutions, and accelerate implementation timelines. They focus entirely on improving performance—freeing your team to focus on their work.

For a deeper look at these benefits and how they translate into measurable improvements, see our article on Key Benefits of CAD Consulting.

How Do CAD Consultants Help Optimize or Automate CAD Workflows?

Even the most advanced CAD systems can fall short if workflows are inefficient or overly manual. CAD consultants begin by conducting a comprehensive workflow assessment, analyzing how design data moves through your organization, where bottlenecks occur, and which tasks could be automated. This evaluation often reveals repetitive steps that drain work hours, such as manual data entry or standards enforcement.

Once those opportunities are identified, consultants can use tools like AutoLISP, .NET, and iLogic automation to streamline day-to-day operations. These automations reduce human error and even significantly cut project times.

What Is Included in a Typical CAD Consulting Engagement (Scope & Deliverables)?

A CAD consulting engagement begins with understanding how your team works today. This includes looking at current workflows—and then mapping out a plan for improvement. As outlined in our overview of Phases of a CAD Consulting Engagement, consultants typically start with an initial assessment to identify inefficiencies and define clear objectives before moving into solution design and implementation.

Most engagements include steps such as gap analysis, configuration and deployment, and training and validation to ensure smooth adoption. They can also include specialized elements like CAD health checks, template standardization, or custom automation. Along the way, consultants deliver tangible assets that drive measurable results and support long-term improvement. You can explore examples of these outcomes in our discussion of typical consulting project deliverables.

By the end of a consulting engagement, organizations walk away with more than optimized software—they gain scalable systems and teams equipped to maintain and build on that success.

How Do I Know if My Team Needs a CAD Software Health Check?

Even the most capable design teams can hit performance walls if their CAD environment isn’t optimized. Over time, standards drift and files become disorganized—slowing projects and creating frustration. A CAD software health check provides a structured way to uncover these issues before they start affecting quality or delivery.

As outlined in Top Signs Your Team Needs a CAD Health Check, telltale indicators include inconsistent drawing standards, repetitive manual tasks, frequent rework, or slow performance when handling large projects. Teams may also struggle to integrate CAD with other systems or adopt new software versions effectively.

What Are Common Challenges in CAD Software Implementation—and How Do Consultants Solve Them?

Upgrading or implementing CAD software can be more complex than it appears. A recent study found that around 70% of large digital transformation efforts fail to deliver their intended outcomes due to challenges like poor planning or lack of adoption. In CAD deployments, those risks appear as resistance to change, data migration headaches, inconsistent standards across teams, and integration conflicts with existing systems.

As discussed in our overview of Best Practices for CAD Software Implementation, CAD consultants help mitigate these challenges by establishing phased rollout plans, validating data integrity, and training users to adapt confidently. Their structured approach minimizes disruption while ensuring that new systems deliver measurable, long-term value.

How Can a Consultant Support Migrating Legacy CAD Data and Systems?

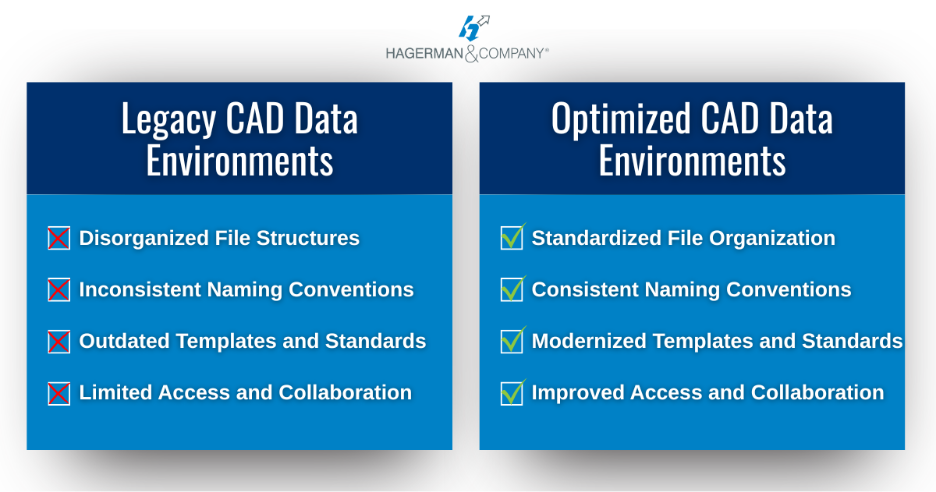

Migrating legacy CAD systems is a high-risk undertaking. In fact, nearly three-quarters of organizations that begin modernization projects never complete them, often due to misaligned priorities, lack of governance, or technical challenges. That’s why expert planning and structured execution are so critical in CAD migrations.

The migration process often begins with assessing your current CAD environment: what data to migrate, what to archive, and how to standardize naming, metadata, and folder structure. Using automation scripts, API conversions, or batch processing, consultants can migrate data while preserving design history and integrity.

Beyond pure data movement, consultants help ensure seamless integration with enterprise systems like PLM, ERP, or PDM. This ensures that CAD assets don’t just “move,” but continue working as part of your end-to-end engineering systems. For a closer look at why shifting away from legacy environments and into cloud-based CAD software matters, explore our deeper dive on migrating legacy CAD data and systems.

How Do Consultants Approach Training or Upskilling In-House Staff?

A consultant’s role isn’t limited to delivering tools and automation; it includes enabling your team to actually use and extend those capabilities. The best training engagements begin with a training needs assessment, where consultants review current skills and map training plans aligned to project goals. This ensures that new workflows, automation tools, and standards get adopted, not ignored.

Training delivery takes many forms: live instructor-led workshops, hands-on labs, self-paced modules, and ongoing mentorship. For example, at Hagerman & Company, every class in the training course catalog can be scheduled as a public session or customized to your environment. This flexibility allows consultants to tailor the material to your workflows and design challenges like this example from Eriez Manufacturing.

By weaving training into the consulting project rather than leaving it as an afterthought, consultants ensure that improvements are sustainable. Your team gains confidence, your workflows become more consistent, and knowledge transfer happens organically—not just from “the consultant knows how,” but “your team knows how going forward.”

For a deeper look at how consultants approach training and certification, see our expanded post on consultant-led CAD training and upskilling.

What Do CAD Consulting Projects Cost, and What Kind of ROI Can I Expect?

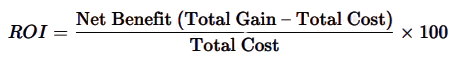

The cost of a CAD consulting engagement varies depending on project scope and system complexity. However, the return on investment (ROI) is often the bigger story. For many organizations, consulting delivers measurable savings through reduced rework, faster project delivery, and better use of engineering resources.

Common ROI Calculations

| Basic ROI Formula: |  |

| Time Savings Model: | |

| Rework Reduction Model: | |

| Efficiency & Throughput Model: | |

| Comprehensive Value Framework: |

Using these models, organizations can calculate both short-term efficiency gains and the broader, strategic value of process improvement. The result isn’t just lower project costs, it’s a stronger, more scalable foundation for design and data management.

Can Solutions and Support Be Provided Remotely or Virtually?

Solutions can absolutely be supported remotely or virtually. Most CAD consulting services today can be delivered remotely with the same depth and precision as on-site engagements. With secure screen sharing, cloud-based project environments, and virtual collaboration tools, consultants can conduct training and provide ongoing support without travel or disruption.

Virtual delivery also makes it easier to scale support across multiple locations. Teams can receive expert guidance in real time; access recorded sessions for future reference and get troubleshooting help as issues arise. Consultants typically use secure remote access protocols and non-disclosure agreements to ensure data protection and intellectual property security throughout the process.

For many organizations, virtual consulting offers flexibility and efficiency—reducing project costs and timelines while maintaining the same hands-on experience as an in-person engagement.

What Best Practices Do Consultants Recommend for Standardizing CAD Templates, Libraries, or Workflows?

Standardizing CAD templates, libraries, and workflows is one of the most effective ways to improve design quality and reduce rework. When teams use inconsistent templates or naming conventions, even small discrepancies can lead to errors and wasted time. Consultants help organizations establish companywide standards that ensure consistency no matter who’s working on the project.

Studies on CAD productivity have shown that consistency and automation within CAD environments are key contributors to faster project delivery and fewer design errors. At the same time, striking the right balance between flexibility and structure is essential. As noted in our blog on Avoiding Customization and Promoting Standardization, over-customization can erode long-term maintainability and complicate future upgrades—making it harder to stay efficient as tools evolve.

Consultants typically recommend a structured approach that includes:

- Conducting a standards audit to identify inconsistencies in templates, styles, and file structures.

- Developing a centralized standards library with approved title blocks, metadata, and component templates.

- Automating template and library deployment through tools like Autodesk Vault or shared drives.

- Documenting standards and governance so updates remain controlled and traceable.

- Reviewing regularly to ensure standards stay aligned with evolving software and project needs.

By embedding these practices into the daily design process, organizations create a more predictable, scalable, and collaborative CAD environment where teams can focus on innovation instead of managing inconsistency.

What Should I Expect as Ongoing Support After a Consulting or Implementation Project?

After implementation, ongoing CAD support ensures your systems continue to perform optimally as tools, teams, and projects evolve. Consultants typically provide structured support programs that include:

- Tiered support options: Choose from flexible levels of engagement ranging from on-demand troubleshooting to proactive optimization and managed support plans.

- System optimization & upgrades: Regular reviews of templates, standards, and configurations to stay aligned with new software versions and performance improvements.

- Continuous improvement planning: Periodic assessments to identify process bottlenecks, training gaps, and opportunities for automation or workflow refinement.

- Troubleshooting resources: Access to technical support, documentation libraries, and escalation channels for complex design or software issues.

- Training & knowledge transfer: Continued education, like this one through Hagerman’s training and support resources, ensures teams remain confident and up to date.

- Long-term partnership: A focus on building internal capability while maintaining external expertise for specialized needs and evolving technologies.

This structured approach to support helps teams minimize downtime, maximize software ROI, and continuously improve their CAD environments over time.

How Does a CAD Consultant Ensure Data Security and IP Protection?

Sensitive CAD data and intellectual property are major assets, so breaches carry real risks. In fact, the Ponemon Institute shared that the average cost of a data breach globally reached $4.88 million, rising 10% year-over-year.

To protect against that kind of exposure, consultants embed security protocols into every stage of a project:

- Non-disclosure agreements (NDAs) and confidentiality clauses to formalize commitments

- Encrypted data transfer and secure storage, including VPNs and cloud encryption

- Access controls and role-based permissions, especially within CAD systems like Vault, PLM, or PDM

- Version control and audit trails, tracking who changes what and when

- Compliance checks aligned to standards like ISO 27001, ITAR, or others as relevant

Consultants also help design long-term governance around data lifecycles (like archival, retention, and secure offboarding of users) so your CAD environment stays safe even as it evolves over time.

Can a Consultant Customize CAD Solutions for Our Industry?

Yes, experienced CAD consultants can tailor solutions to fit the specific workflows, standards, and data structures of your industry. Whether your team works in AEC, manufacturing, or product design, consultants help configure tools and automations that align with your goals. They can streamline submittal workflows, automate drawing generation, or connect your CAD environment with PLM and ERP systems for more seamless collaboration.

Typical industry-specific customizations include:

- Automated drawing and model generation for repetitive design tasks

- Custom BOM synchronization with ERP systems

- Template and standards development for AEC or manufacturing conventions

- PLM/ERP integrations for better data sharing and traceability

- Custom scripts or add-ins for automating repetitive workflows

- Tailored naming conventions and data management rules

By aligning technology with real-world processes, consultants ensure your CAD environment supports productivity and scalability without the risks of over-customization that can complicate future upgrades.

How do Consultants Help Solve Specific Modeling or Geometry Problems?

Modeling or geometry issues can slow entire design projects—whether it’s corrupt geometry, sluggish assemblies, or inefficient workflows. CAD consultants specialize in diagnosing and resolving these problems through a mix of technical expertise, advanced modeling methods, and performance optimization strategies. They start by analyzing the root cause, identifying whether the problem lies in modeling practices, hardware performance, or system configuration, then apply targeted solutions to restore efficiency and accuracy.

Common consultant-driven solutions include:

- Parametric and adaptive modeling techniques for large or complex assemblies

- Surface and mesh repair for resolving geometry and data translation errors

- Feature simplification and optimization to improve model performance

- Rule-based automation using tools like iLogic or Dynamo

- Hardware and system tuning for faster load times and smoother modeling

By applying these best practices, consultants help teams eliminate recurring geometry issues, accelerate design cycles, and maintain reliable, high-performing CAD environments. You can take a deeper dive into this topic by checking out our article How Do Consultants Help Solve Specific Modeling or Geometry Problems?

What’s the Difference Between a CAD Health Check and a Full Implementation Project?

A CAD health check is like a diagnostic exam for your design environment. It identifies inefficiencies, configuration issues, or workflow gaps that might be holding your team back. These assessments are typically shorter engagements focused on analysis, recommendations, and targeted fixes rather than sweeping changes. They help organizations understand where performance, standards, or user adoption can be improved before investing in a full-scale implementation.

A full implementation project, on the other hand, involves broader system design and deployment—covering everything from template development and data migration to process automation and user training. Health checks often act as a first step toward these larger initiatives, helping define priorities and scope. Consultants can then use those insights to plan a strategic rollout that addresses technical challenges while supporting long-term scalability and collaboration.

What Are the Latest Trends and Best Practices for CAD Adoption in Engineering and Manufacturing?

CAD adoption continues to evolve rapidly as design and manufacturing teams embrace new ways to collaborate, automate, and innovate. Modern trends are being shaped by digital transformation, the growing use of artificial intelligence, and the move toward connected data ecosystems that tie design directly to production.

The shift to cloud-based CAD platforms has accelerated in recent years, allowing distributed teams to work from anywhere and access synchronized data in real time. The global cloud CAD market is expected to grow from $3.9 billion in 2023 to over 10 billion by 2033, reflecting a long-term move toward scalable, collaborative design environments.

Meanwhile, AI-assisted CAD is reshaping how engineers work by automating repetitive modeling tasks, predicting performance outcomes, and enabling generative design. Analysts estimate the AI in CAD market will reach $12.6 billion by 2033, growing at over 18% annually.

To take advantage of these emerging tools, consultants recommend a balanced adoption strategy grounded in best practices such as:

- Adopting cloud-enabled CAD platforms to enable real-time collaboration and reduce infrastructure costs.

- Integrating CAD with PLM and ERP systems to ensure connected data and traceability across the product lifecycle.

- Investing in user training and change management to increase adoption and minimize resistance.

- Establishing clear data standards and governance to maintain consistency and version control.

- Tracking ROI and performance metrics to measure the impact of digital transformation efforts.

By combining forward-looking technology with disciplined implementation and user enablement, organizations can position CAD as a strategic driver of innovation—bridging design, production, and data in ways that enhance quality and accelerate delivery.

Transform Your CAD Operations with Expert Consulting

From optimizing templates and automating workflows to training teams and securing data, CAD consulting is about more than just fixing software issues, it’s about creating a sustainable foundation for better design performance and collaboration. Whether you’re addressing specific challenges through a targeted health check or pursuing a full-scale implementation, working with the right partner ensures your systems and people evolve together.

At Hagerman & Company, our consultants help organizations across AEC, manufacturing, and product design translate technology into measurable business results. Through decades of experience, we’ve guided teams toward greater efficiency, consistency, and innovation—no matter their starting point.

If your organization is ready to improve productivity, standardize processes, or modernize its CAD environment, explore our CAD Consulting Solutions or connect with our team to start the conversation!

Comments