In manufacturing plants, each process is an opportunity to engineer improvements to save costs and time. And one such time-consuming process that’s often overlooked is engineering document management. Traditionally, this is a manual, paper intensive process, prone to disorganization.

Drawings and documents alike used to live in file cabinets for years. Now, everything is going digital. This makes trying to keep track of everything, like document versions and who has access to what, harder than ever.

Improving document management can be facilitated through technology. In the fast paced, ever-changing marketplace, the advantages offered by technology should not be ignored. In fact, Tim Shinbara – Vice President and CTO for the Association for Manufacturing Technology is quoted as saying:

“I suspect 2023 will realize increased tech utilization to improve the process itself with some evolutionary advancements in the tech.”

While he was not focusing on document management, we felt his quote spoke true to all factors of manufacturing. Evolutionary advancements are sometimes only considered to be in the field of robotics or AI, yet the greatest advantages can be achieved through improving simple processes. Document management is one such process that can have a significant impact in manufacturing.

In this article, we discuss how a document management system works and how manufacturers can gain efficiencies by using this technology to their advantage.

Key Trends Impacting Manufacturing Plants

Once an industry that accounted for a large workforce, this is no longer the case. Increased automation is becoming the norm in manufacturing plants with fewer processes requiring human input.

Additionally, changes in manufacturing are being driven by consumer expectations as well as supply chain challenges. A major consideration for manufacturers is how to become more resilient to disruptions.

Greater visibility of processes may highlight opportunities for improvement, but there remains a need to be able to accurately document this. And more importantly for the documented data to be easily available to those who need it.

This is especially relevant when considering how new environmental, health and safety (EHS) regulations will require manufacturers to report on how they source and process materials. Digitizing document management is an essential part of this.

How Does a Document Management System Work in Manufacturing?

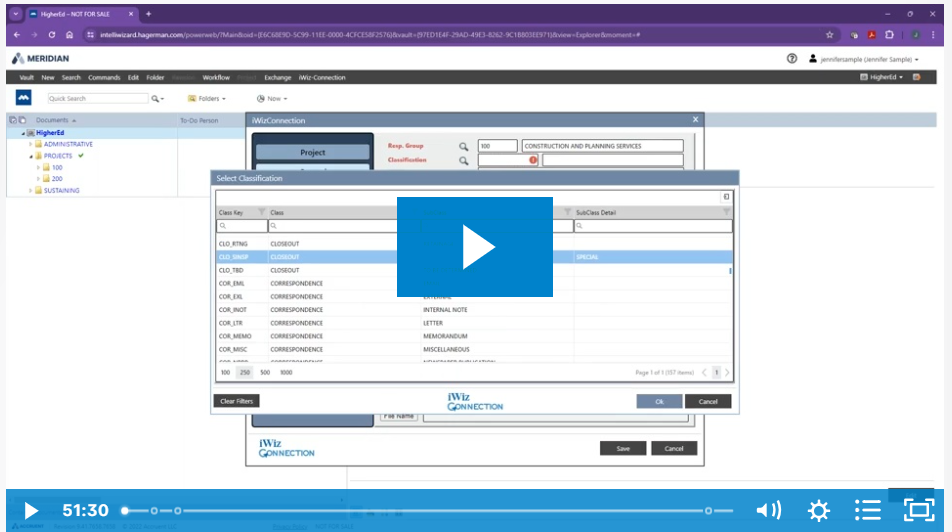

Identifying a need to improve your EDM software is often not enough to convince decision-makers it should be optimized as a priority. But understanding the benefits of optimizing your current system, like Autodesk Vault or Meridian, can be a more compelling argument.

Having an efficient digital process provides a better solution to creating, storing and organizing documentation. This creates a central repository of documents that make it easier to oversee and manage the manufacturing process.

Using an engineering document management system optimally can be distilled into these 10 steps:

1. Create Documents to Integrate with Manufacturing Processes

Use an engineering document management (EDM) system to generate change orders, bills of material, etc.

2. Acquire Documents and Utilize the Data Effectively

Aside from scanning in documents, advanced technologies such as Optical Character Recognition (OCR) can be applied. This converts scanned documents into data that can be searched and edited. This is a significant improvement on manual systems where documents are simply filed away and afterwards become difficult to access and update.

3. Index Documents Making Them More Usable

Consider the benefits of being able to easily search for specific documents relating to a process, product, or project. This can be achieved by indexing documents using keywords and metadata. Data on the author or type of document could also be captured enabling further search parameters.

4. Maintain a Central Document Repository

Whether document storage takes place in the cloud or on premises, having it in a central location has multiple benefits. It makes security and organization simpler. With a central repository it is also easier to assign access to individuals based on their roles or level of management.

5. Secure Documents and Access to Data

Controlling and tracking access to the data contained in documents is also simplified with a DMS. The system automatically logs all activity on the system including which documents were accessed and by who. This provides a clear and traceable audit trail. High level access can be assigned according to individuals and the roles they serve, ensuring that sensitive information is only made available to those authorized by the DMS.

6. Streamline Access to Information

Providing employees with a better process to easily search for the information they need can help streamline and speed up processes. They no longer have to put a request through to another department and then wait for that department to have the time to respond. With a manufacturing-focused DMS, employees can search for documents by document type, date, keyword, or any other type of metadata that has been captured in the indexing system.

7. Improve Collaboration Across the Company

An optimized DMS enables better collaboration and simplifies version control for document editing. EDM systems actively prevent multiple people from editing simultaneously so that conflicting changes are not made, which promotes better collaboration among employees.

Anyone using the document can see who else has access to it and what they’re working on, and changes can be collaborated on in real time. Read this example of how improved collaboration was achieved with proper support. Autodesk Docs enables collaboration by integrating with Autodesk Vault and Meridian respectively.

8. Optimize Workflow Management

Certain processes can be automated in the DMS which can help keep processes on track by prompting outstanding actions. For example: if an invoice requires approval and this hasn’t been given after a certain number of days, then the person who needs to grant the approval can be notified that it’s overdue.

9. Enhance Document Hygiene

A manufacturing plant document retention policy needs to be backed up by an efficient archival and deletion process. This ensures that the company stays compliant with regulatory requirements and that documents are accurately deleted or archived in accordance with the document lifecycle.

10. Implement Document Backup and Recovery

An engineering document management system can help secure company data through regularly backing up documents and having a recovery process in place. With cybersecurity a concern, it’s essential that plants take the necessary steps to protect against data loss. An optimized DMS can help to automate this to support data protection.

Understanding how a document management system works in manufacturing also highlights the benefits that can be gained. Getting specialized support to help your DMS become more organized will help you better manage documents and free up engineers to focus on other areas of process improvement in manufacturing plants. With time and cost savings a priority, leveraging technology is a must.

For more information on how manufacturing leaders are transforming factory design through technology, read our free guide:

Comments