It’s common for experienced engineers to rely on a familiar subset of Autodesk Inventor features. While these longstanding practices may have their merits, relying only on basic functionality can limit the potential of a tool as powerful as Autodesk Inventor.

While many seasoned professionals already know CAD basics, harnessing Inventor’s full capabilities, such as parametric modeling, simulation, and automation, requires specialized training. According to a 2024 workforce survey, many organizations report a significant skills gap, particularly in strategic problem-solving and technical innovation. For engineers, this underscores that training helps bridge the gap between basic and advanced capabilities.

At first glance, training may seem like a disruption, especially when balancing short-term project pressures with the goal of long-term productivity gains. However, expert-led training pays off in measurable ways. Even engineers with decades of experience in other CAD systems will find value in training.

Read through to learn the pros and cons of Autodesk Inventor training and how partnering with the right experts can make the difference between reaping the benefits and misallocating investment.

Pros of Autodesk Inventor Training

Autodesk Inventor is built to simplify complex engineering tasks, but its most powerful features can only be fully leveraged with proper training. As your team masters advanced tools, you'll see significant productivity, accuracy, and collaboration gains. Let’s detail how these benefits can enhance your team’s performance.

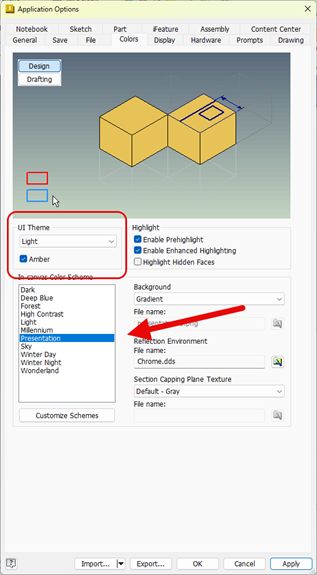

Advanced Parametric Design Mastery

Modifying complex designs quickly can be a headache. Here’s a trick every engineer wishes they knew how to do: Making large-scale changes by simply adjusting a few parameters. It is possible – if you know your way around the tool.

Without professional training, the real power of parametric design might remain out of reach. Accommodating last-minute client changes, for instance, without needing to redo half of your model, is doable with the right training. Turning the usually frustrating requests into something easily manageable gives you the flexibility to keep things on track.

Assembly and Constraint Management

If you’ve dealt with large assemblies, you are probably familiar with how quickly things can get complicated. Keeping track of all the constraints and relationships between components can feel like juggling flaming torches. Here’s where training makes the difference: Allowing your teams to learn how to manage constraints effectively ensures your complex assemblies stay organized and don’t tank your system’s performance.

The need for trial and error is reduced, leading to more accurate simulations and fewer headaches related to mechanical motion issues.

Streamlined Bill of Materials (BOM) Creation and Management

Inventor’s BOM automation is meant for shortcuts, that is, if you know how to use it to its full potential. Proper training means you won’t just generate BOMs; you can customize them to fit your specific project needs, manufacturing workflows, and timelines.

It’s your team’s way to turn tedious tasks into time-savers. By cutting down manual data entry and avoiding inaccuracies, you’ll save hours in production planning and procurement, further minimizing the risk of ordering the wrong parts.

Enhanced FEA (Finite Element Analysis) and Simulation Accuracy

Inventor has the tools to make sure your designs hold up in the real world, from stress analysis to thermal simulations. Misusing these features can lead to serious miscalculations. The last thing you want is to trust a simulation that turns out to be off because of incorrect boundary conditions or load setups.

Professional training will give you confidence that your simulations are accurate. It’s more than just running tests; it's about getting the right results the first time.

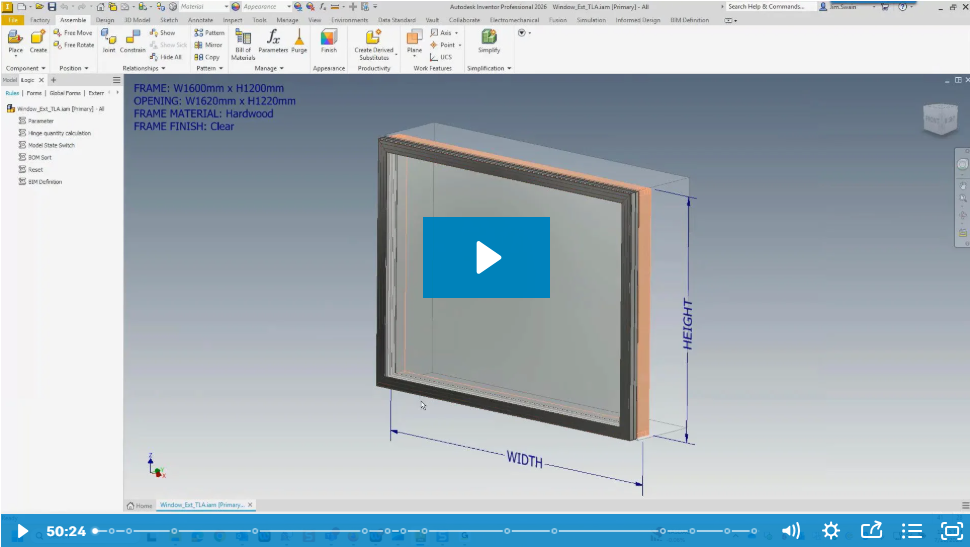

Automation through iLogic

Inventor’s iLogic is a game-changer when it comes to repetitive tasks. Your team can save a ton of time and reduce human error as this feature helps in automating design rules and creating intelligent models. Without the right training, this feature often goes underutilized.

Once you learn how to implement automation properly, those tedious, repetitive tasks free up your time for the things that really matter, like innovating.

Cons of Autodesk Inventor Training

Autodesk Inventor training is highly beneficial, but like any training, it presents challenges that make leaders think twice. However, these roadblocks can be managed with the right solutions so that teams can unlock long-term productivity gains.

Initial Time Investment

Mastering the nuances of Autodesk Inventor comes with a learning curve. The tool's complexity requires a serious time commitment, and for teams under the pressure of tight deadlines, dedicating time to training may seem like a setback. As engineers shift their focus to mastering new tools, production may temporarily slow down.

Solution: Opt for expert instructors who offer flexible, custom training sessions that can fit around your existing schedule. Instead of hitting pause on projects, the right instructors can integrate learning directly into ongoing work, which allows for:

-

Teams acquiring new skills in real-time

-

Immediate applications to live projects

-

Additional post-training support where teams can access quick references or refresher sessions as needed

-

Continuous learning without sacrificing productivity

Cost of Professional Training Programs

Professional training, on any tools for that matter, is often seen as costly, especially for companies working within tight training budgets. High-level, tailored courses might seem out of reach, even though the long-term return on investment is significant.

Solution: Work with instructors who provide personalized training programs so you can optimize both cost and content. Book a consultation first to get an accurate estimate based on your team’s specific needs. The right instructor will tailor the course and ensure that you're getting the value where it counts.

Skill Plateau Risk

Engineers with extensive CAD experience might feel they don’t need further training, especially if they’ve already mastered other systems, which can lead to a "skill plateau." As a result, only basic or intermediate features of Inventor are used, leaving powerful tools like automation or advanced simulations untapped.

Solution: Live demonstrations and real-time assessments from expert instructors can break through that plateau. Personalized evaluations help identify areas where you can push past basic functionalities and get the most out of Inventor. This approach helps teams discover how advanced features can improve workflow efficiency and enhance overall output.

Disruption to Legacy Workflows

Resistance from teams is often more pronounced when transitioning from older CAD systems or manual processes to Inventor. Disrupting established workflows may feel unsettling for members as they adjust to the new tools, leading to a temporary dip in productivity.

Solution: The key here is to work with professionals who understand the intricacies of workflow transitions. Try a phased implementation approach to minimize disruption, which allows your team to gradually integrate new tools while maintaining their day-to-day responsibilities. This sustainable method ensures they master new skills at a manageable pace without the stress of halting production for a full training week.

Overwhelming Features and Modules

With such a broad range of features and modules, Inventor can feel like information overload. Without structured, ongoing support, it’s easy to forget advanced functions after training, leaving engineers scrambling when they need to use these tools in real projects.

Solution: Engage with instructors who provide comprehensive, in-depth training courses tailored to the modules most relevant to your projects. From parametric design to iLogic automation, specialized training helps focus learning on the features that will deliver the most value. Post-training support ensures that your team won’t lose momentum—when questions arise, expert guidance is just a call away.

Invest in the Future of Design with Real-World Experts

While the risks of rushing implementation without proper training are real, the benefits of strategic, expert-led instruction far outweigh the initial challenges. Mastering Autodesk Inventor is more than just learning the software. It’s about transforming the way your team approaches design, workflow efficiency, and innovation.

Be critical when choosing structured training programs. Ensure your team is equipped with the skills needed to maximize the Inventor’s full potential. Don’t risk stalled progress due to incomplete knowledge–invest in professional development that drives results.

Explore Hagerman’s scheduled classes, or browse the course catalog to find the Inventor training program that fits your team’s needs. Hagerman’s trainers aren’t just Autodesk Inventor experts—they bring hands-on industry experience to every session. Get foundational skills and advanced modules with training that’s not only practical but transformative for your design workflows.

Comments