There’s a reason Industry 4.0 remains a buzzword over a decade after its introduction. It’s transforming how businesses design, produce, and deliver products. By outsourcing processes to smart machines, manufacturers are now creating data-driven collaborations between people and technology.

Technology is only part of the equation. Successful digitalization requires understanding how to adapt it for specific use cases. Otherwise, businesses will get stuck within siloed environments and miss the true advantage of digitalization.

Autodesk(R) Digital Factory can modernize manufacturing processes with combined advanced engineering, production, and data analytics. Product design and manufacturing teams can take advantage of a silo-free system to achieve effective cross-functional collaboration and increased agility to meet the industry's growing demands.

Read through to explore how Autodesk Digital Factory can greatly improve your team’s collaboration and production agility and how the right experts can help you get the most out of the platform.

Cross-Functional Coordination

Better Team Collaboration

Autodesk Digital Factory is a shared virtual model or a unified platform that strengthens collaboration between engineers, designers, and production teams by working from the same source of truth. The tool lets your team track a product's lifecycle and instantly relay design changes to the manufacturing floor, ultimately preventing costly delays and speeding up the entire production cycle.

Supplier and Vendor Management

Digital Factory was built to integrate shop floor, building, infrastructure, suppliers, and vendors with a connected data flow. It’s a platform that can significantly help improve supplier and vendor management through real-time data and progress updates. With all stakeholders in the loop, a certain level of transparency enables teams to evaluate supplier performance more accurately. These dynamics maintain quality standards and address potential risks before they impact operations.

Workforce Efficiency

Automation

Workforce efficiency is a top priority for businesses looking to stay on top of the volatile market. With Autodesk Digital Factory, your team can integrate automation and real-time insights into your product cycle within a user-friendly interface, shifting their focus from repetitive tasks to more strategic responsibilities.

Rather than manually tracking your throughput, for instance, your team can utilize the platform’s real-time performance monitoring to quickly address any bottlenecks or inefficiencies. Machine learning algorithms within the system also optimize scheduling and predictive maintenance to reduce downtime.

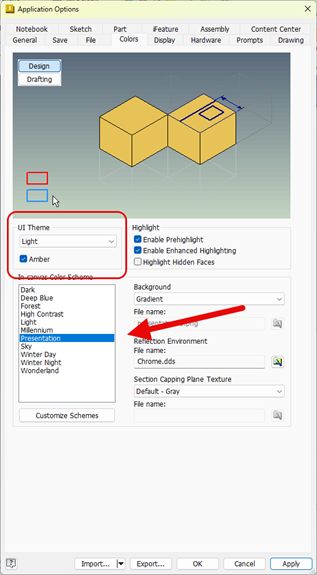

Intuitive User Interface

An intuitive user interface is essential for the smooth adoption of any new technology. Autodesk Digital Factory delivers just that, as the platform is easy to navigate for employees with varying skill levels. With expert training and support, Digital Factory users can operate the system without the typical learning curve.

Greater Agility to Adapt

Factory Simulation

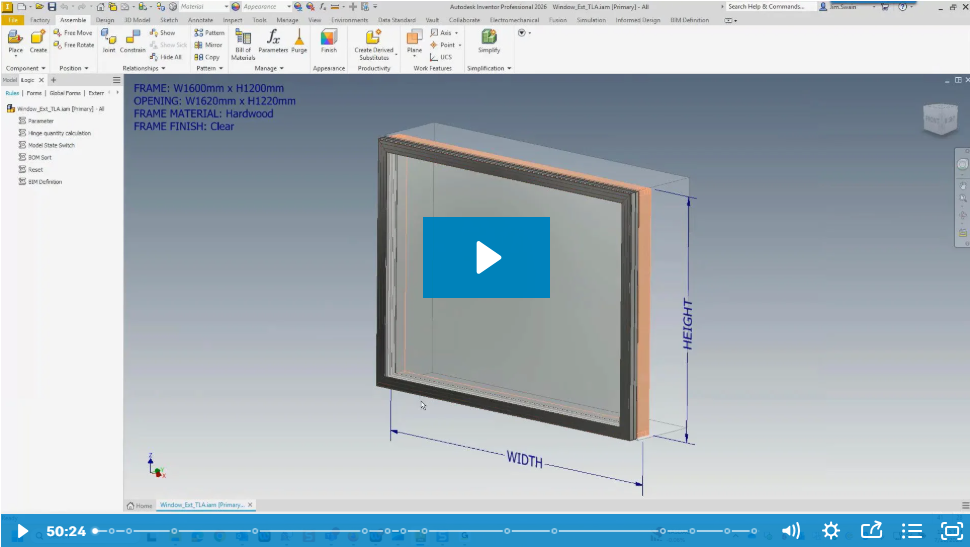

Factory simulation is a powerful feature of Autodesk Digital Factory. Product design and manufacturing teams can test and compare production scenarios based on design changes, bill of materials (BOM), processes, or facilities without disrupting actual operations. Manufacturers can use simulation tools to analyze 3D CAD design geometric and throughput data to identify inefficiencies and opportunities.

This capability becomes invaluable when demand shifts suddenly, or material shortages occur. The COVID-19 pandemic best illustrates the need for this feature. The pandemic proved that markets could shift exponentially and exposed weaknesses across the manufacturing industry. Many companies struggled to quickly adapt to the drastic changes and have yet to recover. Some took months to retool their operations, and the effects are still being felt today. Digital Factory uses predictive analytics to enable advanced scenario planning and help businesses prepare for various operational contingencies.

Cloud-Based Infrastructure

Autodesk’s cloud-based infrastructure offers businesses the agility to adapt quickly, whether they’re entering new markets or responding to seasonal demand changes, all without sacrificing the quality of their output. The cloud platform secures critical data and makes it accessible for remote teams and global operations.

The cloud-based infrastructure enables real-time data capture and analysis to facilitate data-driven decision-making. Having this single data source makes businesses agile and resilient amid demand fluctuations.

Competitive Edge for Digital Factory Adopters

The Digital Factory concept includes technology, machines, tools, and, more importantly, data to enable smart manufacturing. What does this mean for Digital Factory adopters looking to distinguish themselves in the market?

Smart manufacturing, where data is used to make decisions, enables faster time to market, lowers operating costs, and enhances product quality—including customized and sustainable output. This data-driven decision-making uses data analysis through AI to refine processes, minimize waste, and consistently improve product quality. Experts with knowledge of the tools and technologies that form the backbone of smart manufacturing can customize the system and assist your team in setting up data analysis frameworks.

Access the Future of Manufacturing with Real-World Expertise

Implementing Autodesk Digital Factory goes beyond installing the software. It requires thoughtful planning, tailored customization, and a deep understanding of your business’s needs. With decades of industry experience, Hagerman & Company’s team has developed robust strategies and has acquired industry experience to integrate and customize the platform that is just right for your needs. Experts at Hagerman can optimize cross-departmental workflows to align everyone with the same data to minimize errors and enhance consistency across operations.

However, expert support doesn’t end with the technical aspect of the adoption and implementation alone. One common pitfall businesses encounter when embracing the Digital Factory is failing to fully utilize the new software due to inadequate training. When adopting the new platform, your team could benefit from customized Autodesk training.

Autodesk’s vendor management modules can be tailored to streamline communication and significantly reduce lead times. To truly optimize the benefits of Digital Factory, choose an Autodesk partner committed to driving impactful results for your operations.

The Future is Here. Get Started with Autodesk Digital Factory Solutions Today!

The future is promising for businesses that embrace the power of Digital Factories. These companies are better positioned to survive and thrive in the future of manufacturing. Now is the time to redefine your approach to production engineering with Autodesk’s game-changing solution. Hagerman & Company provides the expertise needed to implement and maximize the advantages of Autodesk Digital Factory.

Reach out to Hagerman & Company to learn more about how we can help you succeed with Autodesk Digital Factory solutions.

Attend our upcoming webcast on October 31 and learn more

Comments