Intro

On any given project, you may want to divide equipment and piping into separate drawings. While AutoCAD® Plant 3D allows connections between drawings, it is helpful to know the differences in the behavior of connections. When everything is combined, you can connect pipe to equipment or equipment to pipe using all of the controls provided. When pipe or equipment is moved, the connections are automatically maintained.

However, when an equipment drawing is xref’ed into a piping drawing, there some pros and cons:

|

Pro |

Con |

|

Multiple people can work concurrently on each task of the project. |

You lose the ability to have the Add Pipe Grip (+) on the nozzles of the equipment. |

|

Larger projects can be organized into smaller zones/areas, reducing file sizes and aiding performance. |

When equipment is moved, connections will not update automatically. |

If your project warrants using separate drawings to delegate the work, this article will show you how to reconnect piping to equipment in an xref that has been moved while keeping the time to a minimum.

Example:

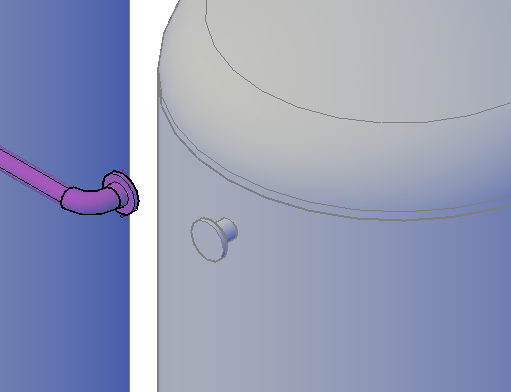

Let’s say there are two drawings named Piping.dwg and Equipment.dwg. The equipment drawing is Xref’ed into the piping drawing, and the piping is connected to the equipment. You open the equipment drawing, move a tank, return to the piping drawing, reload the Xref, and the piping is no longer connected to the tank. See below.

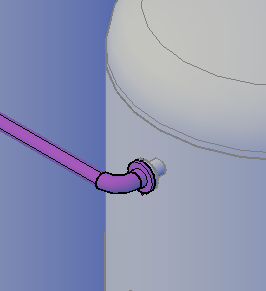

Figure 1: Connection after Xref'ed equipment is moved and reloaded.

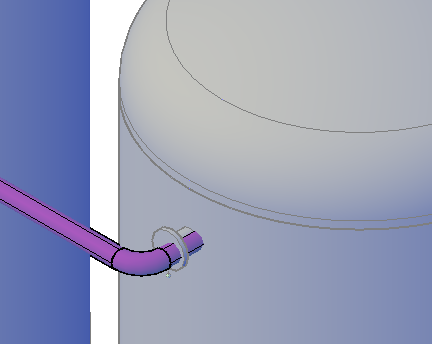

Naturally, you would delete the elbow and flange and reconnect to the nozzle on the tank. The problem is, the pipe won’t reconnect, and that’s the gotcha. See below.

Figure 2: Piping can't reconnect to equipment after modifying in an Xref.

Again, naturally, you might go back to the Xref to look at the equipment nozzle, refresh its properties, move the tank back and try again (and again…), or possibly even delete the nozzle and re-add it. No matter what you do, you'll find yourself spending excess time performing trial and error.

Solution:

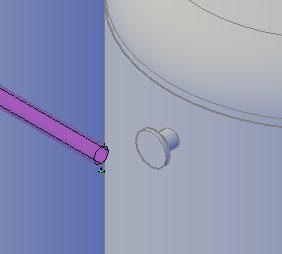

Try it this way. First, in the piping drawing, delete the flange and elbow.

Figure 3: Connection removed BEFORE moving equipment.

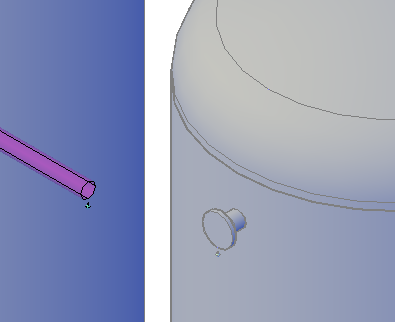

Next, go to the equipment drawing and move the equipment. Save the drawing, go back to the piping drawing, and reload the Xref. See below.

Figure 4: AFTER equipment moved and Xref reloaded.

At this point, all you do is select the pipe, click the ‘+’ control, snap to the node of the nozzle, and the piping will be reconnected. See below.

Figure 5: Pipe reconnected to equipment.

Conclusion

While it is apparent that you still have to reconnect the piping, just by changing the order in which you perform this kind of move will eliminate the extra trial and error trying to figure out why the two won’t reconnect or how to accomplish it. So remember, when equipment is in one drawing and Xref’ed into a piping drawing, disconnect from the equipment first. Move the equipment, save/reload the Xref, and reconnect the piping to rebuild the connection.

Comments