Aerospace & Defense (A&D) organizations face some of the most demanding design and manufacturing challenges in the world, from intricate assemblies and strict compliance standards to global supply chain risk. In this high-stakes environment, even small inefficiencies can cause costly delays or compromise performance and safety.

To stay competitive, today’s leading manufacturers are leaning on integrated digital strategies that combine CAD (Computer-Aided Design), PDM (Product Data Management), and PLM (Product Lifecycle Management). These technologies give engineering teams greater visibility, tighter control over data, and streamlined processes that scale with demand.

For over four decades, Hagerman & Company has helped A&D teams modernize their design and manufacturing workflows through Autodesk-powered platforms and strategic consulting. In this article, we explore the most pressing challenges faced by A&D manufacturers—and how Hagerman’s expertise helps overcome them with smart, scalable solutions.

Top Challenges Facing Aerospace & Defense Manufacturers

Navigating Regulatory Compliance and Audit Readiness

Strict industry standards—such as ITAR, DFARS, AS9100, and NIST 800-171—require rigorous documentation, traceability, and secure access to data. Meeting these obligations consistently across projects is an ongoing challenge, particularly when relying on manual processes or disconnected systems.

By implementing tools like Autodesk Vault and Fusion Manage, A&D companies can automatically generate audit trails, maintain strict version control, and enforce role-based access. Hagerman helps configure these systems to fit your regulatory framework, ensuring compliance doesn’t slow down productivity. With centralized data and automated workflows, teams can respond to audits quickly, minimize risks, and maintain trust with government and private stakeholders alike.

Securing Sensitive Design Data

In a sector that handles high-value intellectual property and defense contracts, protecting sensitive design data is non-negotiable. Cybersecurity threats, unauthorized access, and compliance lapses can have devastating financial and reputational consequences.

To address this, Hagerman equips clients with robust data protection strategies using Autodesk Vault and the cloud-native Fusion Manage. These platforms offer industry-grade encryption, granular access controls, and real-time monitoring to keep data secure at every stage. Hagerman ensures your digital infrastructure aligns with frameworks like CMMC, giving your team confidence that critical information is safe and only accessible to those who need it.

Maintaining Quality Control and Assurance

When safety and performance are on the line, quality is everything. Yet many A&D teams still rely on disconnected tools or outdated processes that make it difficult to catch issues early. This leads to rework, delays, and added costs.

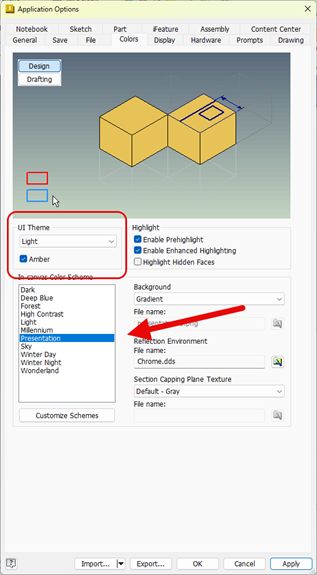

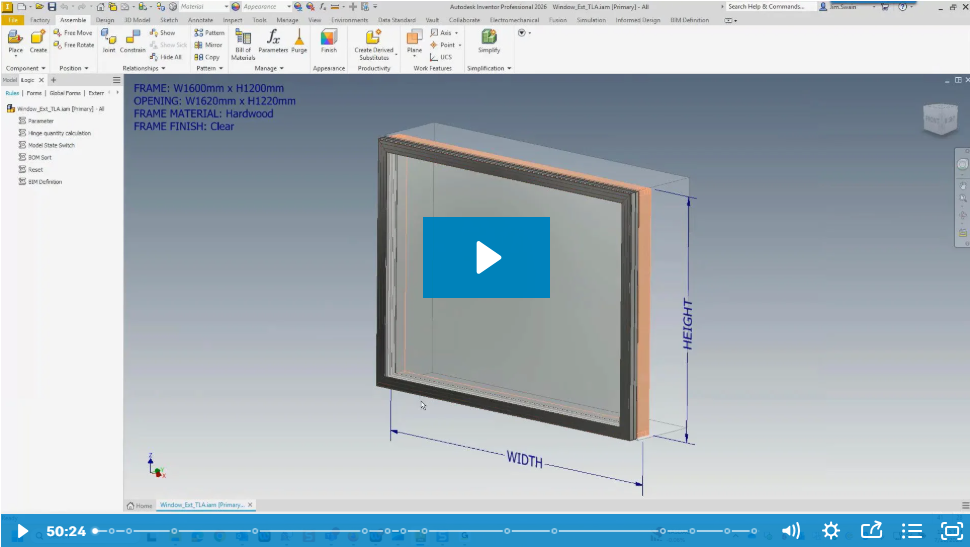

Hagerman helps manufacturers enforce quality from the start by integrating Autodesk Inventor and Vault into the design and production lifecycle. These tools enable advanced simulation, real-world testing, and automated inspections. With quality control built into the workflow, teams can catch design flaws earlier, reduce variability, and ensure every product meets the industry's most demanding standards.

Streamlining Complex Product Development Cycles

A&D programs often involve large assemblies, long lead times, and distributed teams—factors that make coordination especially challenging. Without a centralized system for managing data and changes, even small errors can derail schedules and budgets.

By implementing Autodesk Vault PLM, Hagerman helps organizations bring structure to the chaos. With real-time access to centralized product data and built-in change management tools, teams reduce errors and stay aligned across the entire development process. Hagerman tailors these platforms to support engineering change orders (ECOs), bill of materials (BOM) synchronization, and version control ensuring projects stay on track from concept to launch.

Managing Supply Chain Complexity and Risk

A&D supply chains are global, intricate, and highly sensitive to disruption. Delays, quality lapses, or communication gaps with suppliers can stall production and affect overall program success.

Hagerman addresses these challenges by leveraging Autodesk Fusion Manage and Vault for seamless integration of PLM data and real-time supplier collaboration. These platforms also enable predictive analytics and enhanced traceability. Procurement teams gain full visibility into supplier performance and inventory, while engineers and project managers can align sourcing with development timelines, reducing the risk of bottlenecks or last-minute surprises.

Controlling Costs and Accelerating Time-to-Market

Between budget constraints and tight delivery schedules, A&D companies must find ways to do more with less. Manual workflows, redundant data entry, and inefficient processes can quickly erode margins and extend time-to-market.

Through expert solutions, Hagerman helps teams automate critical tasks such as design simulation, prototyping, and documentation. By working closely with teams to identify friction points, Hagerman streamlines operations, eliminates redundancies, improves accuracy, and reduces engineering overhead—resulting in long-term cost savings. These efficiencies empower companies with the agility to meet deadlines without compromising on quality or compliance.

Developing a Skilled Workforce

As the industry adopts newer, more sophisticated tools, ensuring your workforce is properly trained becomes essential. Outdated skill sets and poor onboarding practices can lead to underutilized technology and lost productivity.

Hagerman solves this with live-instructor led training courses and custom training programs tailored to your specific software stack—whether it’s Autodesk Inventor, Vault, Fusion, or PLM platforms. With flexible delivery options and real-time support, Hagerman helps onboard new users quickly, boost tool adoption, and ensure teams continue evolving alongside the technology.

Preparing for the Future of Aerospace & Defense

The future of aerospace and defense is being shaped by rapid technological evolution—and organizations that modernize now are best positioned to lead tomorrow. Trends like Digital Twins, AI-powered engineering, cloud collaboration, and cybersecurity-driven design are already transforming how teams operate.

With the right tools and a robust data strategy from our experts, Hagerman empowers A&D manufacturers to stay ahead of the curve. These tools offer real-time modeling, predictive maintenance, generative design, and secure, cloud-enabled collaboration—capabilities that will define the next generation of aerospace innovation. As standards and technologies continue to shift, Hagerman ensures that your systems are ready to adapt, scale, and thrive.

Built for the Challenges of Today and Tomorrow

The Aerospace & Defense industry faces a unique convergence of challenges from navigating complex compliance requirements to managing sprawling product development cycles. Success depends on having the right digital tools in place, backed by expert guidance and long-term support.

With more than 40 years of experience and deep industry knowledge, Hagerman & Company delivers the Autodesk-powered solutions A&D teams need to streamline operations, secure data, and stay competitive in a high-pressure environment.

Download our free eBook to dive deeper into how Hagerman empowers A&D manufacturers with scalable, compliant digital solutions.

Ready to take the next step? Contact us today to modernize your operations and build for the future of aerospace and defense.

Comments