Customer Challenge

Customer Challenge

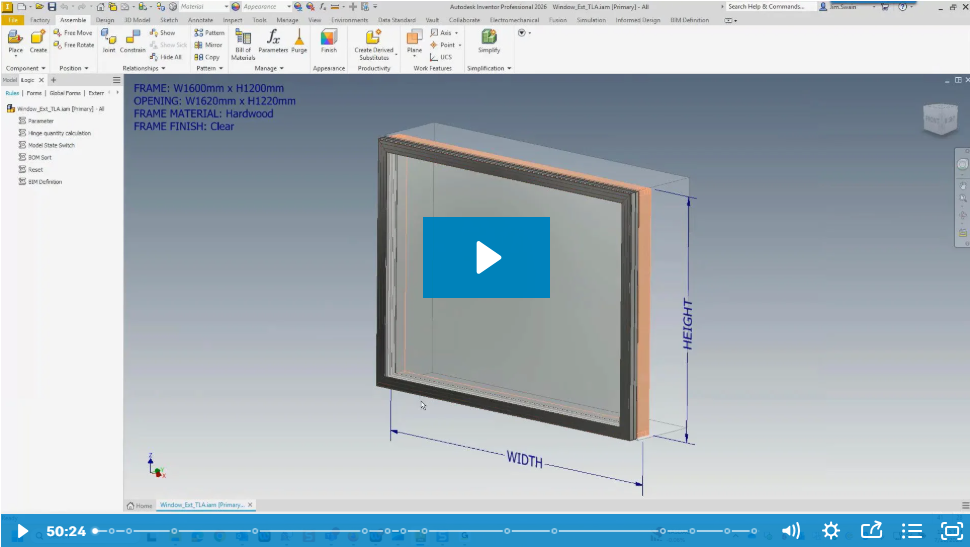

As a custom machine builder, early approval of the design concept is very important for Planet Tool & Engineering. At Hagerman & Company, we looked for ways to explain and illustrate machine functionality to the customer so they can make knowledgeable decisions based on their end needs. Simulation software is a great way to effectively demonstrate operational characteristics and obtain design verification. Once it is obtained, the detailed design is completed and sent to production.

Project Goals

The main goal is always to meet the SOW the first time, thus eliminating redesign and rework. Obtaining early design verification utilizing a virtual simulation of machine functionality is one of the tools used to mitigate that risk. It serves as a communication tool to ensure that the product, as built, will function to meet the requirements, eliminating costly redesign and rework.

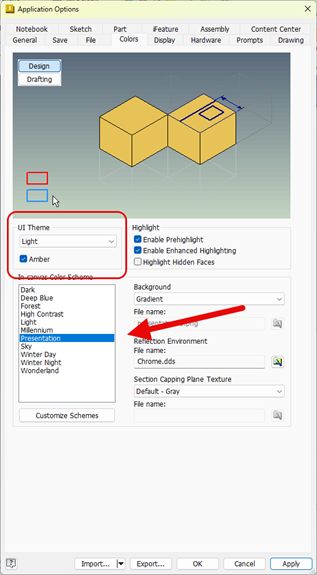

Solution

Training and technical support allowed Planet Tool & Engineering to utilize the software to its potential, making for an effective simulation.

Business Outcome

The simulation software reduced the amount of time required during product validation (run-off) thanks to the machine operation virtually on the computer. There are no "surprises" when the machine is built and operational. All interested parties were able to watch it function before it was built. Additionally, Autodesk Inventor Nastran stress analysis software allowed the customer to utilize less material in the design, reducing cost and increasing production efficiency.

Conclusion

The user-friendly interface of Inventor made the engagement fun and faster. It is exciting to get to see and show machine functionality prior to building it and then see it physically work after it is built.

About Planet Tool & Engineering

About Planet Tool & Engineering

Since 1965, Planet Tool & Engineering provides innovative solutions to a diverse manufacturing industry. They continually upgrade and automate their machining capabilities in order to operate more cost effectively and efficiently.

"It is exciting to get to see and show machine functionality prior to building it and then see it physically work after it is built."

Comments