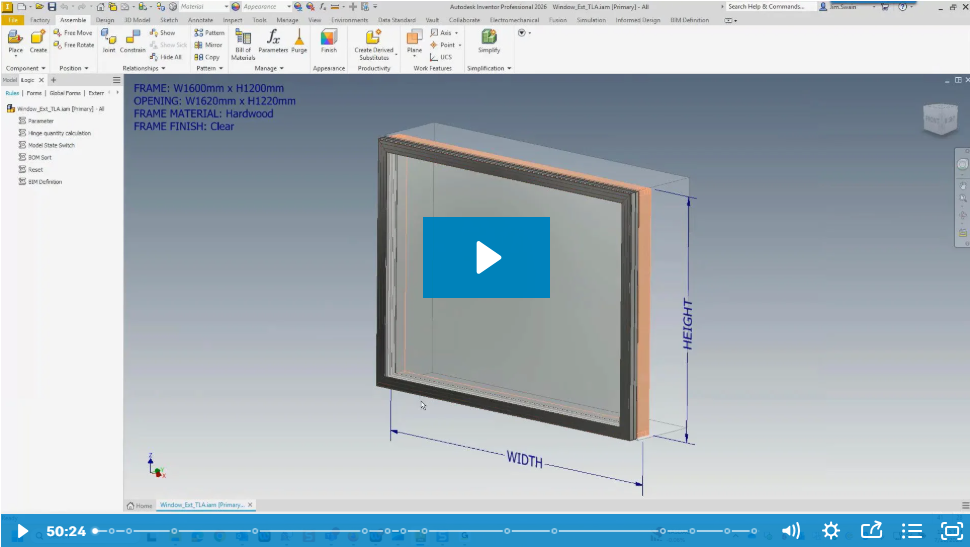

Benda Conveyor Solutions, a leading provider of conveyor systems and automation technology, recognized the need to optimize their engineering processes in order to meet increasing project demand. As they continued to rely on Autodesk® Inventor and iLogic for design automation, the team began to experience inefficiencies and workflow interruptions—especially following an upgrade to Inventor.

To address these challenges, Benda engaged Hagerman & Company, their long-time technology and consulting partner, to help refine and update their iLogic automation.

Project Goals:

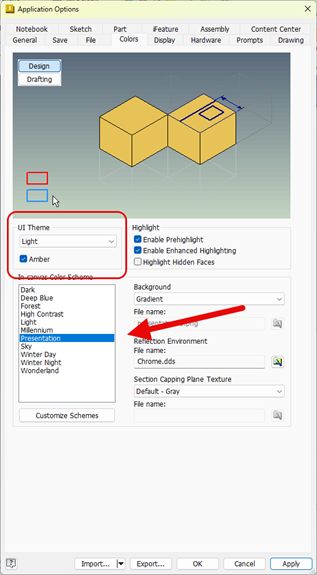

Benda’s engineering team had created a custom iLogic setup over time to streamline repetitive tasks like part configuration and documentation. However, some of the automation scripts had grown unwieldy or incompatible with the latest Inventor version. The goals of the project were to:

- Update and stabilize iLogic code for Inventor

- Eliminate recurring error messages

- Remove unnecessary prompts and manual steps

- Improve overall efficiency and scalability of the automation tools

Solutions:

Hagerman & Company assigned Senior Solutions Consultant Mike Space to work directly with Benda’s engineering team. Mike collaborated closely with their internal stakeholders to review, refactor, and optimize the existing codebase.

One particularly memorable issue involved a function that generated DXF files. As one Benda engineer shared:

“One of the functions in our code to generate DXF files required the user to press 'Enter' after each part was processed. With some of our assemblies having over a hundred sheet metal parts, this was more of an annoyance than a benefit. I even engineered a physical ‘Enter button holder downer automation device’ to bypass it—freeing me up to adjust my caffeine and nicotine levels while the process ran.”

Though the workaround was clever (and arguably patent-worthy), Mike was able to go directly into the code and remove the redundant function altogether. This small change alone drastically improved unattended operation and saved valuable time.

In addition to this fix, Mike cleaned up the broader code logic, removed obsolete scripts, and implemented best practices for long-term maintainability and version compatibility.

“It was a great experience working with Mike and the Hagerman team. We’ve already identified more projects in the pipeline as we continue to do more with less, increasing both the efficiency and profitability of our engineering department.”- Al Popovich, Senior Mechanical Design Engineer

Business Outcomes:

Thanks to these enhancements, Benda Conveyor Solutions has improved their internal workflows, reduced manual intervention, and eliminated unnecessary bottlenecks. With their automation system now running smoothly, the engineering team can focus on higher-value work and take on additional projects without increasing overhead—directly contributing to greater productivity and profitability.

Conclusion:

Benda’s collaboration with Hagerman & Company and Autodesk resulted in more than just a technical fix—it created a foundation for continued efficiency and growth. By modernizing their iLogic automation and resolving pain points, Benda Conveyor Solutions is better equipped to meet customer demands and scale their operations intelligently.

Sometimes, solving a problem doesn’t require duct tape—or an “Enter button holder downer”—just the right partner.

Comments