Autodesk’s Integrated Factory Modeling (IFM) is reshaping how teams approach factory design by enabling seamless integration of mechanical, architectural, and production data. In a recent webinar hosted by Hagerman & Company, industry experts explored how Autodesk® tools such as Inventor®, Factory Design Utilities, and Autodesk Docs bring cohesion to a typically segmented design process. The IFM approach promotes real-time collaboration and centralized data management across departments—ensuring that everyone, from engineers to project managers, has access to up-to-date information from any device. This unified digital environment fosters efficiency and collaboration, helping teams stay aligned and reduce errors that can lead to delays and budget overruns.

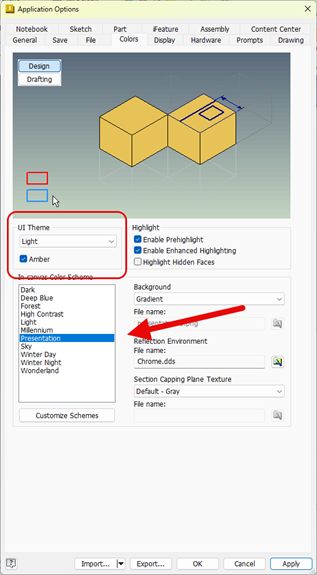

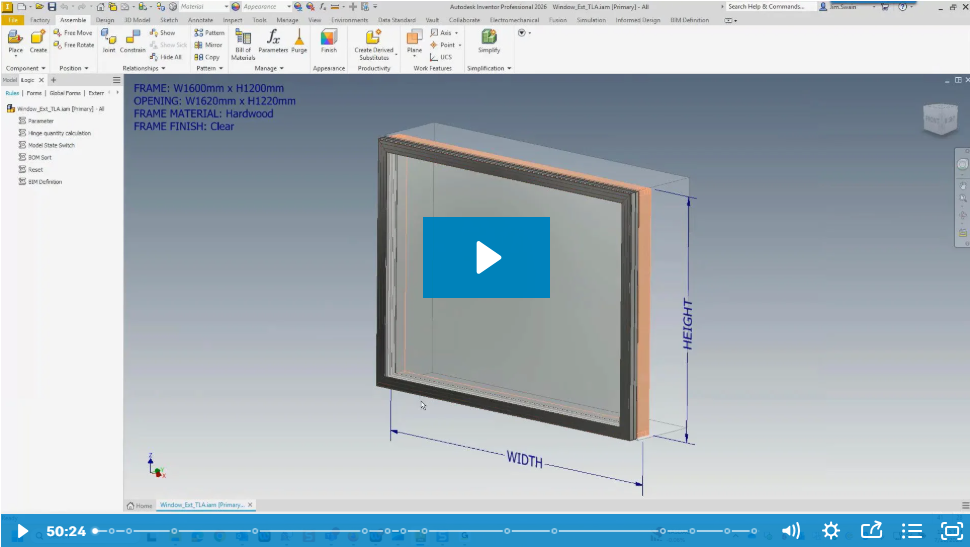

One of the key challenges in factory planning is the fragmented nature of design and data-sharing systems, with various departments often using separate tools and file types. IFM addresses this by linking data directly through Autodesk Docs, enabling stakeholders to share layouts and models in real-time. For example, by using Factory Design Utilities within Inventor, AutoCAD®, or Navisworks®, teams can create both 2D and 3D layouts that automatically sync across platforms. This setup allows for seamless updates: changes made in Inventor, for instance, are immediately reflected in AutoCAD and accessible in Docs, minimizing the lag between design adjustments and broader team visibility. This live syncing keeps all departments—from MEP and electrical to production—aligned with accurate information, reducing the risk of miscommunication and duplicated efforts.

Through this model, IFM not only facilitates better communication but also helps streamline processes by automating layout changes and synchronizing component updates across various project phases. Components and assemblies created in Inventor can easily be shared with Revit, thanks to AnyCAD functionality, allowing architectural teams to integrate mechanical models directly into the building layout. Moreover, files stored in Autodesk Docs can be accessed by external stakeholders, such as contractors and vendors, without the need for constant exporting and emailing. This setup fosters a truly collaborative ecosystem where teams can make decisions faster and with greater confidence, ultimately helping companies launch products more efficiently, meet sustainability goals, and stay competitive.

To learn more about how Autodesk’s Integrated Factory Modeling can transform your factory projects, watch the full recording of Hagerman & Company’s webinar for a comprehensive walkthrough and expert insights.

Comments