There is a lot to learn and take advantage of when it comes to AutoCAD Plant 3D(™). Integrating diverse data from various sources to create an accurate 3D model is a complex process that can be both time-consuming and error-prone if you’re not familiar with the nuances of AutoCAD Plant 3D.

There is a lot to learn and take advantage of when it comes to AutoCAD Plant 3D™. Integrating diverse data from various sources to create an accurate 3D model is a complex process that can be both time-consuming and error-prone if you’re not familiar with the nuances of AutoCAD Plant 3D.

AutoCAD Plant 3D includes a robust database with pre-configured ASME/ANSI and DIN specifications; however, users often need to enrich these databases with custom components to meet their unique project requirements. This process can be resource-intensive and requires a strong understanding of the software and advanced customization skills.

These are just a few frustrations engineers can face when using AutoCAD Plant 3D without fully understanding its capabilities. With an SQL database on the back end functioning more like a BIM tool, Plant 3D is an entirely different beast. Winging it is not an option if you want the best project outcomes. While there are plenty of video tutorials online, they often miss the nuts and bolts essential for a thorough understanding of the software.

The Benefits of Training for AutoCAD Plant 3D

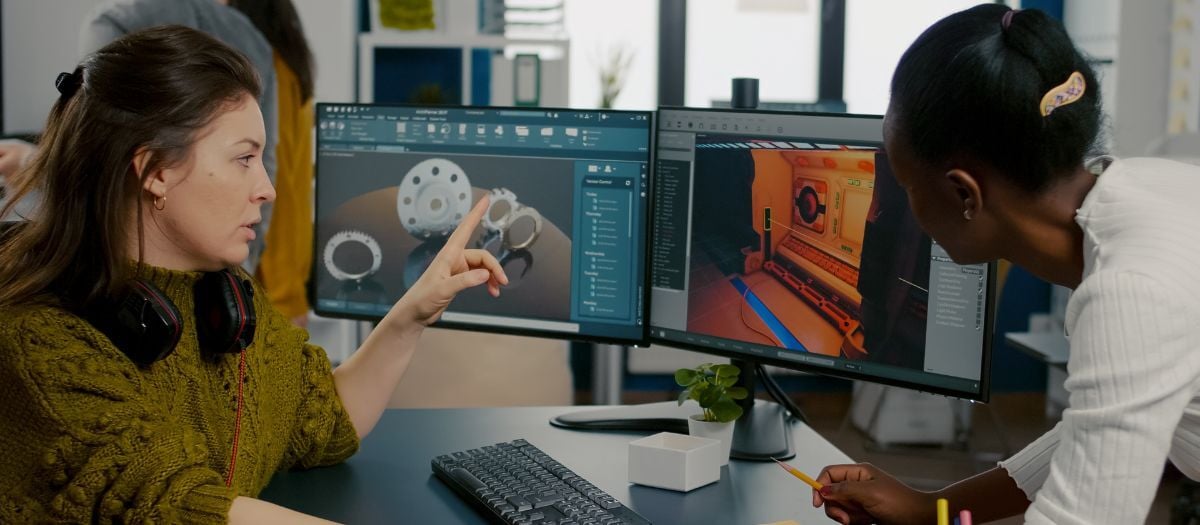

AutoCAD Plant 3D is a specialized software application for the process, power, and plant design industries. Used at its full potential, its 3D design and simulation capabilities significantly boost project accuracy and execution.

The real value of AutoCAD Plant 3D lies in its mastery through detailed training with experts. Here’s how investing in expert-led training can help:

Multidisciplinary integration for comprehensive design

Meeting rigorous documentation requirements can be a significant challenge. Engineers are often required to create extensive technical documentation that includes schemes, general location and isometric plans, and a material list for pipeline installations. Making sure that all these documents meet the client's specific requirements can be tedious.

AutoCAD Plant 3D enables seamless integration into a single platform across various disciplines—piping, equipment, civil, and structural design. Mastering this feature lets you streamline workflows with dedicated modules for creating and managing P&IDs, 3D pipeline routes, equipment models, and structural elements.

Better design visualization for accuracy and planning

Understanding the spatial relationships between various components in a facility is crucial for engineers. With the right AutoCAD Plant 3D experience, engineers can effectively identify potential design issues, such as clashes between piping and structural elements, providing valuable insights that help streamline the design process and prevent costly errors.

If, for example, you are working on a wastewater treatment plant, Plant 3D can ensure all components fit seamlessly in a confined space, avoiding expensive redesigns and delays.

More optimized processes with in-context commands and automation

The software’s in-context commands speed up and automate P&ID drafting and 3D modeling, which is a big advantage for large-scale projects. However, learning to use these commands efficiently requires training from experts who can demonstrate best practices. With the right training, you can learn how to automatically generate piping isometric drawings directly from 3D models, dramatically reducing manual work and the risk of errors.

Seamless collaboration in a cloud-based environment

One of AutoCAD Plant 3D’s standout features is its ability to support collaborative design in a cloud-based common data environment. This abilityis especially useful for large, multidisciplinary projects in oil and gas industries where multiple team members or stakeholders collaborate simultaneously. However, training is needed to navigate collaborative tools, manage permissions, and maintain data integrity before teams can utilize this feature.

Reinforced compliance with industry standards and regulations

AutoCAD Plant 3D is designed to comply with various industry standards and regulations, which is crucial for sectors like oil and gas, pharmaceuticals, and hazardous waste management. However, ensuring your design meets those standards involves more than knowing they exist. It requires hands-on training to understand how to implement them within the software.

For example, compliance with ASME standards for piping design (B31.1 and B31.3) or ISO 15926 for data integration requires specialized knowledge of AutoCAD Plant 3D’s settings and validation tools. With expert guidance, users can learn to set up data validation rules that automatically check for compliance issues, reducing the risk of non-compliance and project delays.

Setting Realistic Timelines for Learning AutoCAD Plant 3D

Training for AutoCAD Plant 3D isn’t just for beginners. It benefits managers, senior engineers, and project leads, and mastering it can vary significantly depending on your background, experience, and commitment to learning.

There are two primary training levels available:

-

QuickStart and New User: Ideal for craftspeople and designers who are new to the software.

-

Advanced Training: Perfect for experienced designers, engineers, and CAD managers looking to deepen their expertise.

Each training path comes with recommended prerequisites:

-

P&ID QuickStart and Plant 3D New User require basic knowledge of AutoCAD.

-

P&ID Advanced and Plant 3D Advanced need a solid understanding of the specific software covered in the class.

-

BIM Collaborate Pro for AutoCAD Plant 3D focuses on cloud-based project collaboration and requires foundational knowledge of Plant 3D.

For those looking to get up to speed quickly, there are different training programs available to cater to varying levels of expertise and specific requirements of the software:

-

QuickStart Session: This session provides a foundational overview in just one day (8 hours), perfect for those who need a rapid introduction.

-

P&ID Advanced Course: This is for more in-depth training, which usually spans two days

-

Plant 3D New User Program: This usually takes three days to cover essential concepts comprehensively.

-

Plant 3D Advanced Course: This course usually lasts two days and is for advanced users who want to sharpen their skills.

-

BIM Collaborate Pro for AutoCAD Plant 3D: For those integrating Plant 3D within a collaborative BIM environment, this one-day session is ideal.

Remember: All training times mentioned above are not one-size-fits-all. The journey towards AutoCAD Plant 3D proficiency is shaped by prior experience and how much time you’re willing to invest.

Experienced piping designers switching from another software may take about three months to get comfortable with AutoCAD Plant 3D, with training and self-practice combined. In contrast, those new to piping design could need up to a couple of years to reach an intermediate level as they build foundational skills through courses and hands-on practice.

Maximizing AutoCAD Plant 3D with Hagerman’s Specialized Training

The path to mastery is rarely a straight road. Some users may find themselves plateauing after learning the basics, like converting redline drawings to black P&IDs. That's where Hagerman’s training comes in. It’s not just our expertise in the software itself that makes us stand out. Our training sessions are led by instructors who bring valuable real-world experience to the table. Experts like Rick France and Brett Barkman bring decades of hands-on CAD management experience to every session, offering insights from their extensive careers.

Unlike trainers who learn the software without practical application, the experts and instructors at Hagerman have faced the complexities of real projects across industries like Wastewater Treatment, Oil and gas, and Pharmaceuticals. Their collective expertise allows them to offer training that is theoretical and grounded in practical, applicable knowledge.

Learn to Lead. Don’t Skip Training!

The key takeaway is clear: Investing in the right training and consistently applying what you learn in real-world projects can make all the difference in mastering AutoCAD Plant 3D, regardless of where you start. Here’s what you need to remember before embarking on a journey to mastering AutoCAD Plant 3D:

Invest in training! Skipping training can lead to costly mistakes and missed opportunities. It’s an investment that pays off in smoother workflows and more efficient projects.

Apply what you learn immediately. Don’t wait months to use your new skills– software evolves quickly, and knowledge fades without regular use. Implement your learning as soon as possible to retain the details and adapt to software updates.

Stay engaged. Make the most of your training by asking questions and engaging with instructors. Remember, support doesn’t end when the session does—it's there to help you continue learning.

Trust real-world expertise. Hagerman’s instructors bring experience from diverse industries, such as Wastewater Treatment, Oil & Gas, and Pharmaceuticals, ensuring they understand the context in which you'll be using the software. This practical insight makes a world of difference in the effectiveness of training.

Reach out to Hagerman to maximize your software investment and explore our range of training courses tailored to meet your needs.

Comments