Steel production is a high-pressure industry that demands the optimal use of capital equipment and human resources. Companies constantly grapple with tight deadlines and rigid quality standards. Considering most clients come from critical industries, e.g., construction, automotive, and industrial, production facilities can’t afford to miss targets.

There are several ways to streamline daily operations. However, one of the biggest yet commonly overlooked productivity killers is the overreliance on legacy systems.

Automation will play a transformative role in the steel industry. Clinging to outdated processes causes production errors, manufacturing delays, uncontrolled documents, substandard safety practices, and higher daily expenses. Research shows that steel facilities could cut expenses by 30 to 50 percent just by automating rote work.

In this article, we’ll discuss some common challenges in the steel industry – and how leaders can overcome them.

The Modern Challenges of Managing Steel Production Buildings and Equipment

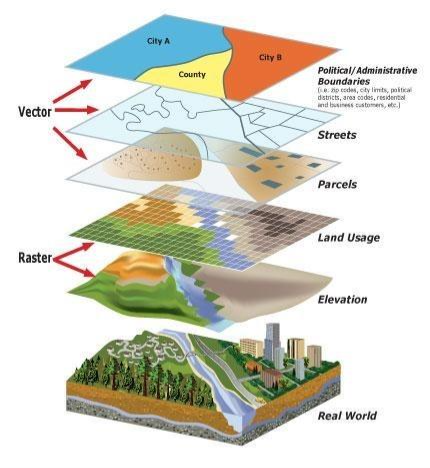

In steel production, a lot of information needs to be stored around internal and external parties. Facilities manage work orders, CAD models, process flow diagrams, as-built drawings, environmental data permits, and safety sheets, among thousands of other files. Not surprisingly, several roadblocks impede effective documentation, which include:

Inefficient Document Access for Plant Staff

Steel production specialists need immediate access to technical documents throughout the steel value chain, from design conceptualization to lifecycle tracking. Unfortunately, traditional document management practices often fall short. These systems struggle to meet the evolving demands of downstream processors, resulting in overworked staff who compensate for the deficiencies.

Redundant and Conflicting Documentation

For steel production facilities, engineering documents typically have several variations. These versions stem from design changes, prototype failures, product revisions, and lifecycle tracking, all stored to repositories. Facilities need to be able to find these documents when needed.

Ineffective Information Retrieval

While sorting through file variations is a hurdle in steel production, the greater challenge is retrieving critical information. Some facilities even hire full-time specialists for this role. Ideally, data retrieval should only take steel specialists and engineers minutes, regardless of location.

Poor Management of Project Handovers

Product lifecycle management extends beyond the design and prototyping phases. Facilities must ensure efficient production, operation, and ultimately, successful product retirement. Unsurprisingly, poor documentation creates inefficiencies. Outdated as-built documents, project drawings, and equipment schema lead to multiple errors in lifecycle management.

External Partner Collaboration Obstacles

Despite the importance of automated PDM and PLM systems for external collaboration, steel production facilities often lack one. Uncontrolled documents create inefficiencies. Most facilities don’t realize how much resources are wasted when business partners, contractors, and downstream processors request drawings and layouts manually.

How Customized Solutions Can Solve These Challenges

Since traditional practices have several documentation challenges, steel production facilities should consider modernizing their database. Here are the ways that custom engineering document management solutions address roadblocks:

Centralized Hub and Automated Workflows

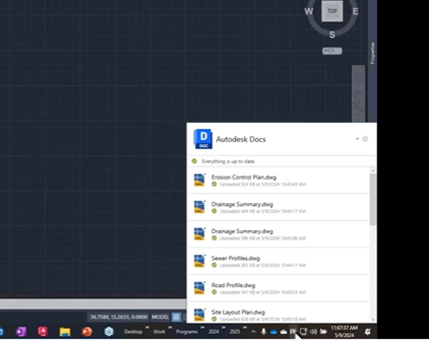

Steel production facilities should invest in product data management (PDM) software to modernize traditional databases. The goal is to create a centralized repository where steel specialists manage and access technical data as needed.

For optimal results, choose PDM tools that mesh well with the design tools you use for drafting. A good option is Autodesk Vault. Specialists integrate it with popular Autodesk design tools and CAD systems like AutoCAD, Revit, and Inventor. Also, while its system requirements are based on physical hardware specifications, the program is available on cloud servers.

Mobile Access and Real-Time Collaboration

Every specialist involved in the steel production process should have access to tech documents regardless of location. Facilities can complement PDM systems with iOS and Android applications like RedEye. It lets users submit due markups, review crucial drawings, and make urgent changes.

RedEye is an excellent option for steel companies with remote engineers and field personnel moving around different sites. Instant access to updated drawings, blueprints, and equipment schema allows for smoother processes.

Secure Collaboration with External Partners

Steel production facilities regularly collaborate with various third parties, like industry associations, compliance bodies like the ISO, equipment suppliers, and downstream processors. These collaborations typically involve different drawings and layouts. Rather than assigning a point person for manual dissemination, create a centralized PDM or PLM system for controlled access to documents.

Tools like Meridian can help here. It offers regulated access for external collaborators, relays concurrent plant modifications, and provides both cloud and on-premise deployment.

As-Built Master Data Management

Facilities can use systems like Meridian as a centralized repository for the documents in project handovers, e.g., as-built drawings and manuals. Its automation function updates revision histories and audit trails. Changes are applied to the necessary files whenever a steel engineer makes design revisions, does quality control, or performs routine maintenance. That way, authorized parties pull relevant, up-to-date information in real-time.

Expertise as an Extension of Your Team

Steel production facilities often struggle with digital data and physical drawings scattered across outdated engineering document management systems (EDMS). This fragmentation jeopardizes data integrity and hampers revision control. To streamline legacy data migration, seek help from PDM and PLM specialists like Hagerman. Some ways that such a partner can help include:

-

System Compatibility: A common issue with legacy data migration is system compatibility. Legacy data, e.g. floor layouts, building drawings, equipment schema, and CAD files, from obsolete tools and physical drawings aren’t always digitized. To overcome this roadblock, facilities must hire document management specialists who can convert legacy data formats en masse.

-

Training and Adoption: Steel production specialists using legacy CAD systems and servers (e.g., Windows or SharePoint) might have trouble navigating modern systems. There’s a learning curve to user adoption. Facilities can hasten the process by partnering with document management specialists who provide training and support for PDM/PLM systems. Equip your team with the necessary skill set to maximize these tools fast.

-

Accurate Data Migration: Metadata, file relationships, and custom properties are accurately transferred to new systems, ensuring data integrity and continuity. Facilities should be able to continue projects where they left off.

How Hagerman Can Digitize the Daily Workflow in Steel Production Facilities

Document management and other software systems can help you maximize productivity rates, but only if you get the right support. Look for tailored solutions customized to steel production facilities. Implementing a generic, poorly planned database will confuse your engineers and technicians, among other industry specialists, inadvertently creating more roadblocks.

Are you ready to digitize your file ecosystem? Consult the specialists at Hagerman & Company. Whether you need to manage steel material data within CAD models or share complex steel fabrication models with external partners, we have you covered.

Floor layouts, building drawings, equipment drawings, paper drawings.

Comments