Why should manufacturers embrace digital transformation? With product cycles shortening, customer expectations rising, and regulations becoming stricter, relying on traditional processes is no longer the best option. Integrating AI, cloud software, ERP platforms, and IoT systems helps teams work smarter, but true growth comes from connecting these technologies throughout the entire product lifecycle.

Many manufacturers still rely on disconnected systems, spreadsheets, or emails to share product data. Engineers work in CAD, production teams operate in ERP, and quality teams use standalone tools, which often leaves everyone relying on outdated information. Having this kind of fragmented approach slows down product development, creates costly errors, and in regulated industries, can even cause compliance risks. The result is reduced agility, missed deadlines, cost overruns, and a weaker ability to respond to customer and market demands.

PLM software solves these challenges by providing a single source of truth for all product data - from CAD files to Bill of Materials (BOMs), to specifications and even change orders. With real-time access to accurate data, design engineers can hand off production without delays, while procurement and quality teams avoid doing manual updates.

This results in smoother collaboration, fewer errors, and a more connected product lifecycle that carries projects from concept to launch with minimal bottlenecks.

How PLM Software Improves Cross-Team Collaboration

Many manufacturers still rely on disconnected systems, spreadsheets, or emails to share product data. Engineers work in CAD, production teams operate in ERP, and quality teams use standalone tools, which often leaves everyone relying on outdated information. Having this kind of fragmented approach slows down product development, creates costly errors, and in regulated industries, can even cause compliance risks. The result is reduced agility, missed deadlines, cost overruns, and a weaker ability to respond to customer and market demands.

PLM software solves these challenges by providing a single source of truth for all product data - from CAD files to Bill of Materials (BOMs), to specifications and even change orders. With real-time access to accurate data, design engineers can hand off production without delays, while procurement and quality teams avoid doing manual updates.

This results in smoother collaboration, fewer errors, and a more connected product lifecycle that carries projects from concept to launch with minimal bottlenecks.

Using PLM Software to Streamline Change Management in Complex Manufacturing Environments

Managing change in a complex environment is one of the toughest challenges that manufacturers face. When engineering change requests are tracked through emails or spreadsheets, critical updates can slip through the cracks which can result in inconsistent reviews, undocumented revisions, and increased compliance risks.

However, if organizations leverage PLM software features such as automated engineering change orders (ECOs), tracked revision histories, and enforced approvals, they can ensure every modification is documented and processed correctly the first time.

Digital audit trails and electronic signatures improve accountability while having standardized workflows shorten approval cycles. For highly regulated industries like aerospace and defense, this level of control is essential, ensuring that every change remains traceable for both regulatory and contractual requirements.

Connecting Engineering to ERP and MES

A critical but often mismanaged area of product development is the handoff between engineering and production. In traditional setups, production and procurement teams rely on either static files or disconnected systems that quickly become outdated. This results in manufacturing errors, excess inventory, and shipment delays which are issues that become especially costly when speed and precision are essential.

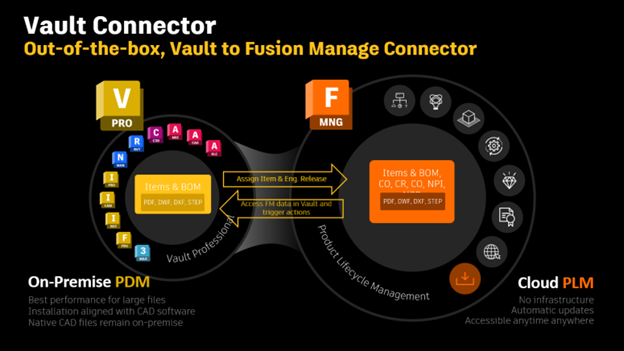

With modern product lifecycle management tools, engineering data flows seamlessly between PLM, ERP, and MES systems. Ensuring version-controlled product data flows directly into production and supply chain environments allows organizations to reduce manual effort and eliminate the risks of outdated information. This reduces manual effort, eliminates costly rework, and accelerates ramp-up once designs are finalized. This is a critical advantage for industries where accuracy and agility directly impact profitability.

Why PLM Software is Critical for Compliance and Traceability in Aerospace and Defense

In industries like aerospace and defense, compliance requirements add another layer of complexity to product engineering and manufacturing. Every change, approval, and decision must be documented to meet standards like ISO, ITAR, AS9100. Without a connected system, this becomes a manual and error-prone process that puts contracts and reputations at risk.

PLM software makes compliance and audit readiness a natural byproduct of daily work. Automated traceability captures every action in the product lifecycle, secure access controls protect sensitive information, and structured workflows ensure that documentation is always complete. This reduces the risk of penalties or rework, providing complete documentation of design and build history, and gives manufacturers the confidence that they are always prepared for an audit.

Improve Design Reuse and Standardization with PLM Software

Another hidden cost for manufacturers is the loss of institutional knowledge. Legacy projects and design files often end up scattered across shared drives,poorly documented, or locked in formats that are difficult to reuse or access. As teams evolve, new engineers may spend significant time recreating solutions that already exist, which wastes resources and slows progress.

Through PLM data management, organizations can turn past designs into reusable assets. Structured part libraries, consistent naming conventions, and advanced searches make it easier for engineers to locate and repurpose solutions. This also helps to accelerate product design, promote standardization, and maximizes the value of existing property.

For organizations managing large product families, intelligent reuse supports scalability, faster time-to-market, and higher quality.

How Hagerman Delivers Connected Product Development Services

The benefits of a modern product lifecycle management system extend far beyond efficiency gains. PLM creates the foundation for accelerating digital transformation by improving collaboration, streamlining change, connecting to ERP and MES, ensuring compliance, and enabling design reuse. It shifts manufacturers from disconnected tools and siloed data towards a more integrated ecosystem where the people, data, and technology work together to drive innovation and growth.

While the benefits of PLM software are clear, success depends on more than just the tool itself. It also involves effective implementation that requires aligning processes, training teams, and integrating systems throughout the organization.

At Hagerman, PLM implementations are not treated as one-off software projects. Rather, they are delivered as a part of a Connected Product Development framework that supports organizations from assessment through continuous improvement.

- Assess and Align: Hagerman begins with a detailed audit of current workflows, systems, and bottlenecks. Having this assessment identifies transformation blockers and establishes measurable success metrics.

- Implementation and Integration: PLM is configured to match actual roles and responsibilities. CAD, ERP, MES, and other enterprise systems are connected to ensure seamless data flow. This step is also where manual processes are replaced with automated workflows.

- Train and Adapt: Adoption is supported through role-based training, onboarding programs, and the cultivation of internal champions. This also ensures that teams are capable and confident in using the system.

- Optimize and Evolve: Over time, Hagerman also helps organizations to expand PLM functionality with supplier portals, simulation data management, and analytics, while continuously refining workflows as teams grow.

This comprehensive approach ensures organizations not only implement PLM successfully but also realize long-term return on investment.

PLM Is the Foundation of Modern and Scalable Product Development

Digital transformation isn’t just about adopting new tools but also about building systems that operate in harmony. PLM software connects the dots throughout manufacturing, engineering, and compliance, creating a unified ecosystem that enables faster innovation, reduces risk, and builds smarter products.

For manufacturers, aerospace suppliers, defense contractors, and the like, connected product development is no longer optional. It’s the foundation of scalability, compliance, and long-term competitiveness.

Ready to simplify compliance and streamline collaboration? Talk to Hagerman today and discover how our expertise and connected product development solutions can help accelerate your transformation and maximize ROI without disruption.

Comments